How Caster Wheel Diameter Impacts Load Capacity and Movement

Feb 4th 2026

Here's the thing: moving equipment shouldn't feel like a workout. Yet in warehouses, workshops, hospitals, and job sites everywhere, people struggle daily to push carts, dollies, and equipment that should roll smoothly. If you've ever found yourself asking, “Why is this so hard to move?”, you're not alone.

Let's break it down. While people often focus on load weight or frame strength, one critical factor is often overlooked: caster wheel diameter. The size of a caster wheel plays a major role in how much weight it can handle and how easily the equipment moves. Get it wrong, and even a moderate load can feel impossible to push. Get it right, and suddenly everything rolls with ease.

Let's discuss how caster wheel diameter impacts load capacity and movement.

What Are Casters?

Casters are the small but powerful wheels mounted to the bottom of carts, racks, furniture, and equipment that allow them to roll instead of being lifted. In simple terms, a caster is a wheeled device attached to an object to make movement easier, safer, and more efficient.

You'll see casters everywhere on warehouse carts, medical equipment, bakery racks, office chairs, and heavy industrial machinery. While they may look simple, casters are carefully designed components that play a major role in how equipment performs.

Casters come in a wide range of sizes, materials, and configurations, each suited for a specific type of job. For example, heavy industrial carts often use large steel or polyurethane caster wheels to support significant weight, while office chairs rely on smaller nylon or rubber casters for smooth movement on finished floors.

Key Highlights

- Casters are wheeled devices that allow carts, racks, and equipment to move safely and efficiently

- They are used across industries, including warehouses, healthcare, food service, and manufacturing

- Casters come in many sizes, materials, and designs to match different loads and environments

- Larger, heavy duty casters support high weights, while smaller casters work best for light loads and smooth floors

- Choosing the right caster improves mobility, safety, and equipment lifespan

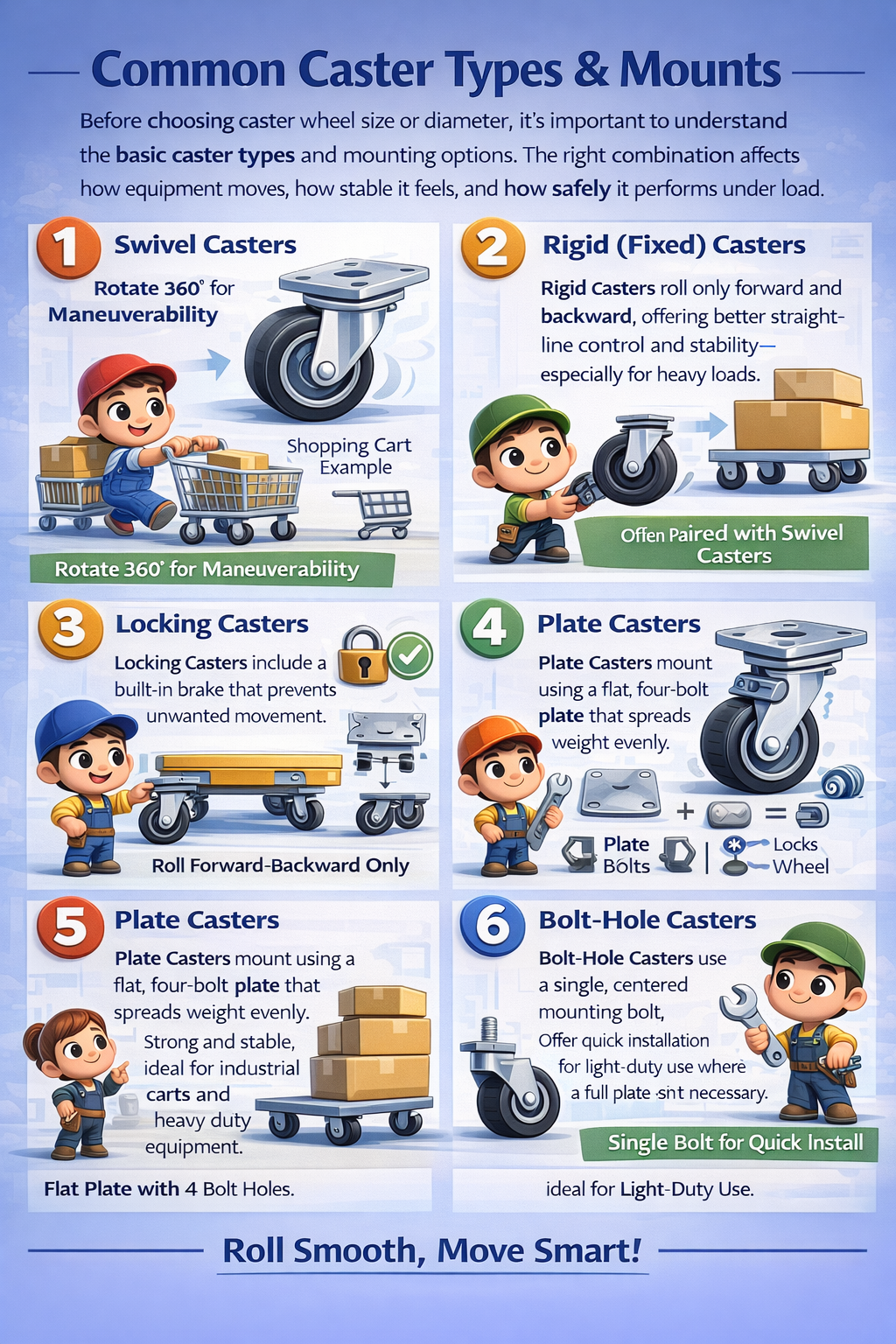

What Are the Common Caster Types and Mounts?

Before choosing caster wheel size or diameter, it's important to understand the basic caster types and mounting options. The right combination affects how equipment moves, how stable it feels, and how safely it performs under load.

1. Swivel Casters

Swivel casters rotate 360 degrees, allowing equipment to turn easily in any direction. They're ideal for tight spaces and frequent direction changes. A shopping cart is a familiar example of swivel casters in action.

2. Rigid (Fixed) Casters

Rigid casters roll only forward and backward, providing better straight-line control and stability, especially for heavy loads. They're often paired with swivel casters to balance steering and tracking.

3. Locking Casters

Locking casters include a built-in brake that prevents unwanted movement once equipment is positioned. Available in swivel and rigid styles, they improve safety on sloped floors and mobile workstations. Some locks secure only the wheel, while others lock both the wheel and swivel.

4. Plate Casters

Plate casters mount using a flat, four-bolt plate that spreads weight evenly. This makes them strong and stable, ideal for industrial carts, machinery, and heavy-duty equipment.

5. Stem Casters

Stem casters mount using a threaded or insert stem. They're easy to install and commonly used on furniture, office chairs, and light-duty carts, though they typically support less weight than plate-mounted casters.

6. Bolt-Hole Casters

Bolt-hole casters use a single, centered mounting bolt. They offer quick installation and are best suited for light-duty applications where a full plate mount isn't required.

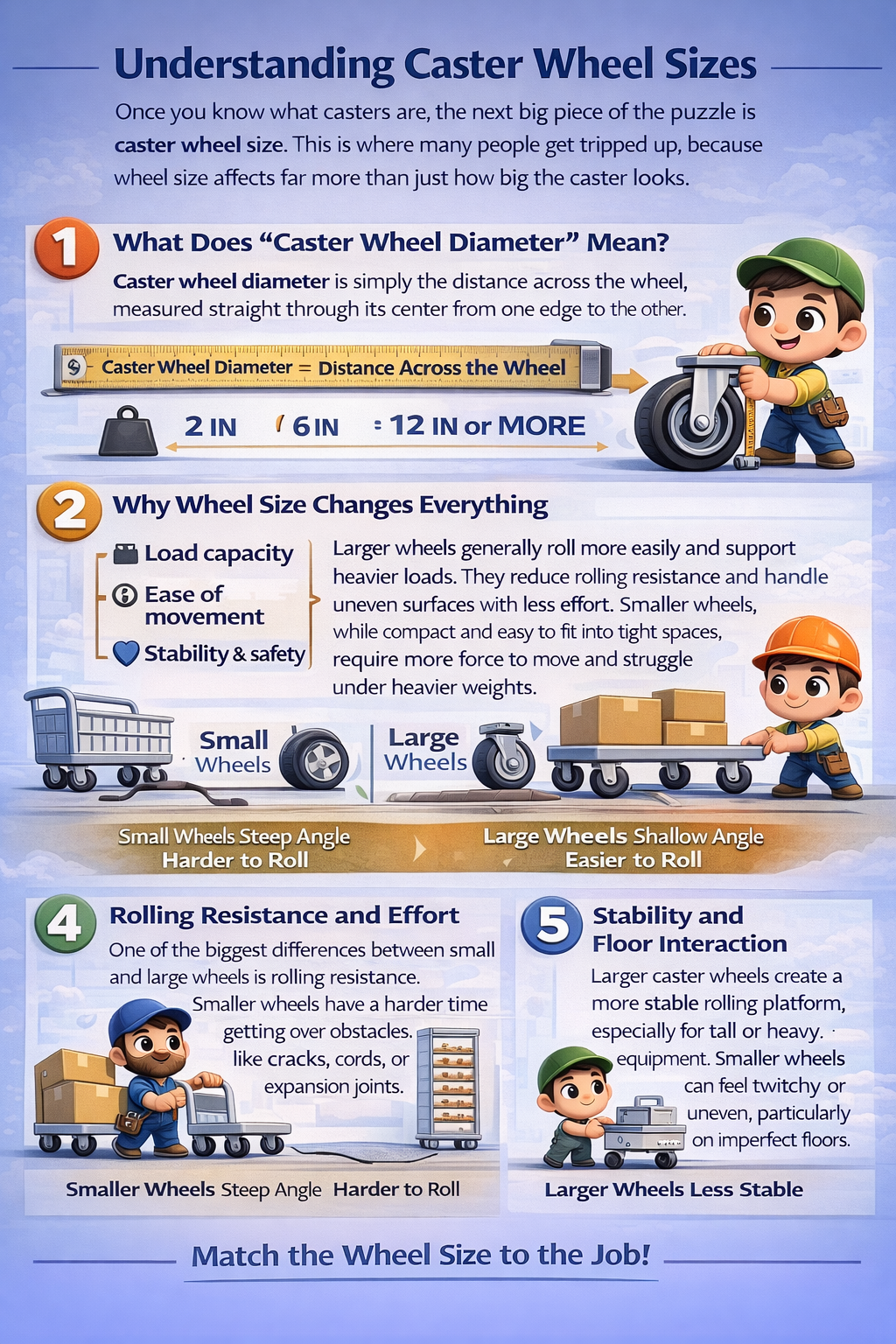

Understanding Caster Wheel Sizes

Once you understand what casters are, the next key factor is caster wheel size. Wheel diameter affects far more than appearance; it directly influences how equipment carries weight, moves, and stays stable.

What Does “Caster Wheel Diameter” Mean?

Caster wheel diameter is the distance across the wheel, measured straight through the center from one edge to the other. Common sizes range from 2 inches to 12 inches or more, and this simple measurement plays a major role in real-world performance.

Why Wheel Size Matters

Caster wheel size impacts three critical areas:

- Load capacity

- Ease of movement

- Stability and safety

Larger wheels support heavier loads, reduce rolling resistance, and handle uneven surfaces more easily. Smaller wheels fit tight spaces but require more effort to move and struggle under heavier weights.

Rolling Resistance and Effort

Small wheels have difficulty rolling over cracks, cords, and floor seams. Larger wheels approach obstacles at a lower angle, allowing them to roll over smoothly instead of stopping short. This is why equipment with larger casters often feels easier to push—even when carrying more weight.

Stability and Floor Interaction

Larger wheels create a more stable rolling platform, especially for tall or heavy equipment. Smaller wheels can feel less stable on imperfect floors, but work well for:

- Light loads

- Smooth indoor surfaces

- Equipment with limited height clearance

The key is choosing a wheel size that matches the load, floor conditions, and available space, not just the smallest or least expensive option.

How to Measure Casters (Without the Guesswork)

Choosing the right caster starts with accurate measurements. Missing even one dimension can lead to poor performance, installation issues, or unsafe equipment. Fortunately, measuring casters is straightforward when you know what to check.

Wheel Diameter

Wheel diameter is the most commonly referenced measurement. Lay the wheel on its side and measure straight across through the center from edge to edge. This is the size listed in caster specifications, such as 4-inch or 6 inch wheels. Because diameter affects both load capacity and rolling ease, accuracy is critical.

Wheel Width

Measure wheel width by standing the wheel upright and measuring from one outer edge to the other. Wider wheels distribute weight more evenly and roll more smoothly over seams, gaps, and uneven surfaces.

Overall Height

Overall height is the distance from the floor to the top of the mounting plate or stem when the caster is installed. This measurement affects equipment height and stability. Even small changes can cause equipment to sit unevenly, so matching the original height is important.

Mounting Plate or Stem Size

To ensure proper fit:

- Plate casters: Measure the plate's length, width, and bolt-hole pattern (center to center).

- Stem casters: Measure the stem's diameter and length.

Correct mounting measurements ensure secure installation without modification.

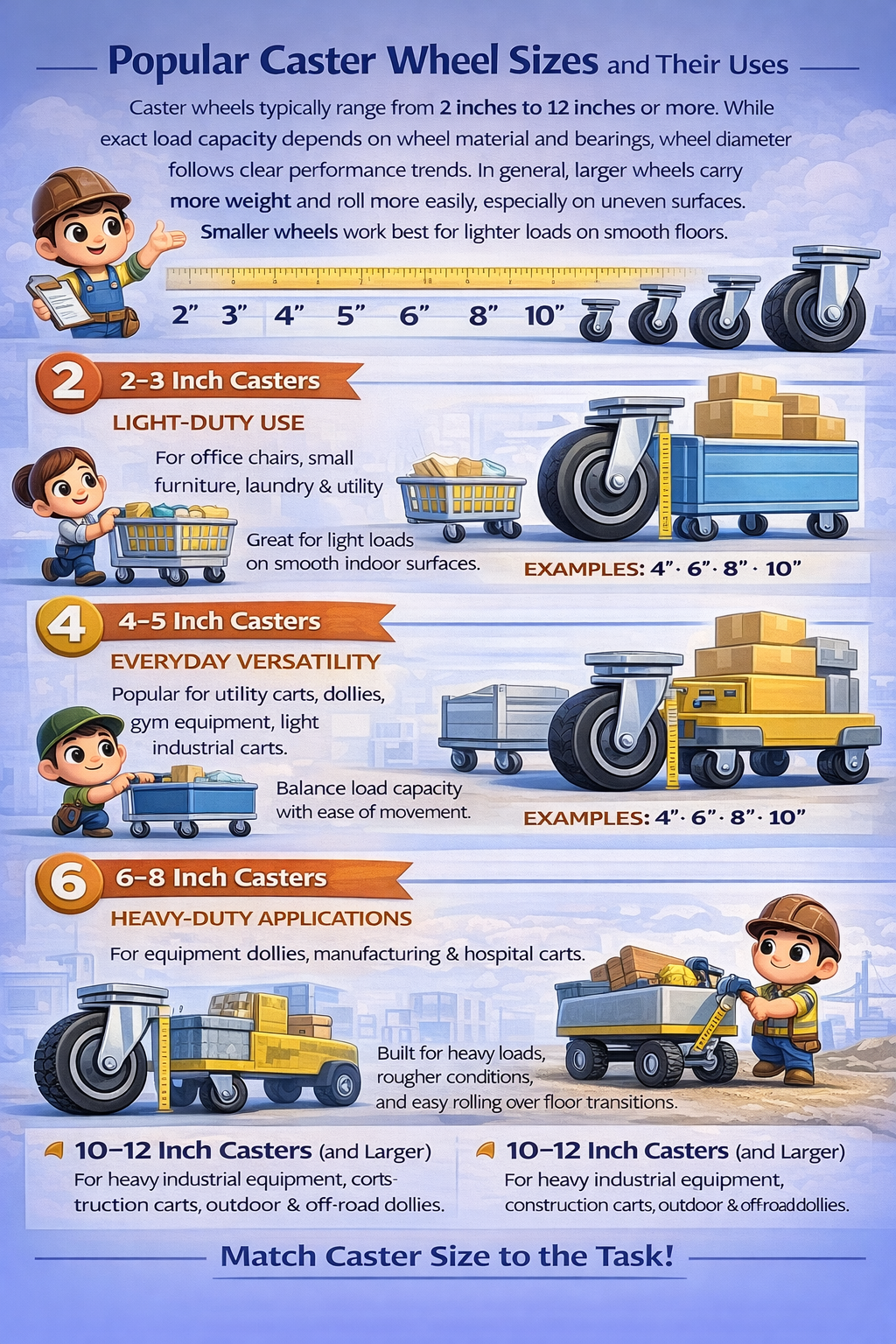

Popular Caster Wheel Sizes and Their Uses

Caster wheels typically range from 2 inches to 12 inches or more. While exact load capacity depends on wheel material and bearings, wheel diameter follows clear performance trends.

In general, larger wheels carry more weight and roll more easily, especially on uneven surfaces. Smaller wheels work best for lighter loads on smooth floors.

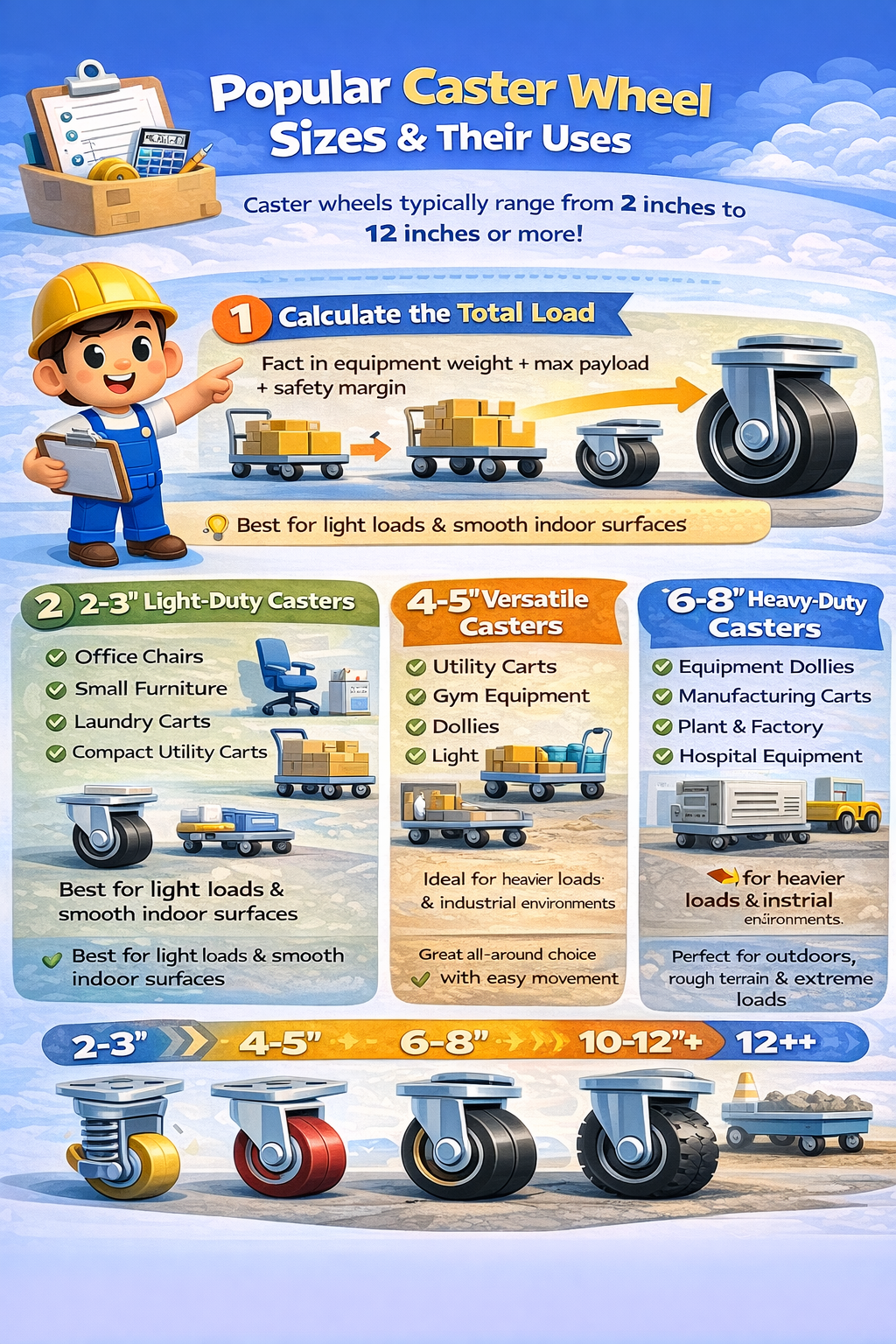

2–3 Inch Casters: Light-Duty Use

Designed for light loads and smooth indoor surfaces, these casters are commonly found on office chairs, small furniture, laundry carts, and compact utility carts. Their low height is helpful where clearance is limited, but they don't handle obstacles or heavy weights well.

4–5 Inch Casters: Everyday Versatility

Four and five inch casters are a popular all-around option. Used on utility carts, dollies, gym equipment, and light industrial carts, they balance load capacity with easy movement. Wheels in this range often use polyurethane or reinforced rubber for smoother rolling and floor protection.

6–8 Inch Casters: Heavy-Duty Applications

Built for heavier loads and tougher environments, 6- to 8 inch casters are common on equipment dollies, manufacturing carts, and hospital equipment. Their larger diameter allows them to roll more easily over cracks and floor transitions, and they are typically paired with durable materials like polyurethane, cast iron, or steel.

10–12 Inch Casters (and Larger): Rough Terrain and Extreme Loads

Very large casters are used for heavy industrial equipment, construction carts, and outdoor or off-road dollies. These wheels handle debris, rough concrete, and uneven ground with ease and are often used in pneumatic designs for added shock absorption.

Special-Purpose Casters: Designed for Demanding Applications

Not all casters are built for the same job. While standard casters handle everyday carts and equipment, some applications require special-purpose casters designed for extreme weight, heat, sanitation, or rough terrain. Choosing the right specialty caster improves safety, durability, and ease of movement.

1. Heavy-Duty Casters

Heavy duty casters support very high loads, often 1,000 pounds or more per caster. They feature large wheel diameters (6–12 inches), reinforced steel frames, and oversized bearings. Common wheel materials include steel, ductile iron, and thick polyurethane. For equipment weighing several thousand pounds, these casters are essential.

2. High-Temperature (Heat-Resistant) Casters

Used in bakeries, commercial kitchens, and industrial settings, heat resistant casters are made from materials like phenolic, thermoplastic, cast iron, or steel that withstand high temperatures. Any equipment near ovens, fryers, or heated racks should use high-temperature casters.

3. Stainless Steel Casters

Stainless steel casters are ideal for food processing and other sanitary environments. They resist corrosion, withstand frequent wash-downs, and are easy to clean. These casters are often paired with non-marking wheels to protect floors while meeting hygiene standards.

4. Non-Marking Casters

Non-marking casters prevent scuffs and marks on floors, making them common in bakeries, hospitals, and cleanrooms. Made from rubber, polyurethane, or nylon, they offer smooth rolling, quiet operation, and good traction.

5. Off-Road and Pneumatic Casters

For outdoor or uneven terrain, pneumatic or foam-filled casters are ideal. Typically 8 inches or larger, these wheels absorb shock and roll easily over gravel, grass, and rough concrete. They're commonly used on outdoor carts and utility equipment.

6. Dolly Casters

Dolly casters are heavy-duty, plate-mounted casters designed for hand trucks and dollies. Built for frequent use and high loads, they usually feature wheels in the 6- to 10-inch range for strength and smooth movement.

7. Custom Casters

When standard options don't fit the application, custom casters provide tailored solutions. These may include unique mounting patterns, specialized wheel materials, oversized frames, or multi-wheel configurations to match specific requirements.

How to Choose the Right Caster

Choosing the right caster comes down to balancing load, environment, and movement needs. Follow these steps to make a confident, reliable choice.

1. Calculate the Total Load

Add the weight of the equipment and its maximum payload, then include a safety margin of about 30 percent to account for uneven weight distribution. Divide that total by the number of casters to determine the minimum load rating per caster, and always round up.

2. Match Wheel Diameter to the Load

Select a wheel diameter rated to support the required load. Larger wheels typically handle more weight and roll more easily. When unsure, choosing a slightly larger wheel helps reduce stress and improve movement.

3. Consider the Floor Type

Soft wheels like polyurethane or rubber protect finished floors, while harder or pneumatic wheels perform better on rough, uneven, or debris-filled surfaces. Uneven floors often benefit from larger or shock-absorbing wheels.

4. Account for Environmental Conditions

Choose materials suited to the environment. Heat-resistant casters are essential in kitchens and bakeries, while stainless steel and sealed components are best for wash-down or corrosive areas.

5. Decide on Mobility Needs

If tight turning and frequent repositioning are required, swivel casters, often with locks, are ideal. For straight-line movement under heavy loads, rigid casters or a combination of rigid and swivel casters offer better control.

6. Check Fit and Mounting

Confirm that the mounting plate or stem size, bolt pattern, and overall height match your equipment. Proper fit is critical for safe installation and long-term performance.

Final Takeaway

Choosing the right caster goes far beyond picking a wheel size. By considering load requirements, environment, floor conditions, and movement needs, you can select casters that improve safety, reduce effort, and extend the life of your equipment. The right caster doesn't just make equipment roll; it makes work easier.

Frequently Asked Questions

1. How does caster wheel diameter affect load capacity?

Caster wheel diameter has a direct impact on how much weight a caster can safely support. Larger wheels distribute weight over a wider area and place less stress on the wheel and bearings. This allows them to carry heavier loads without wearing out or failing prematurely. Smaller wheels concentrate weight in a smaller area, which limits their load capacity and increases wear under heavy use.

2. Does a larger caster wheel make equipment easier to move?

Yes, in most cases it does. Larger caster wheels require less force to start rolling and move more smoothly once in motion. They also handle cracks, debris, and uneven floors more easily than smaller wheels. This reduces pushing effort, improves control, and helps prevent worker fatigue.

3. What caster wheel size is best for heavy equipment?

Heavy equipment typically performs best with caster wheels in the 6-inch to 12-inch range, depending on the total weight and floor conditions. Larger wheels offer higher load capacity, smoother rolling, and better obstacle handling, making them ideal for industrial carts, machinery, and heavy-duty applications.

4. Can small caster wheels safely handle heavy loads?

Generally, no. Small caster wheels are designed for light-duty use and smooth surfaces. When used under heavy loads, they are more likely to flatten, crack, or wear out quickly. Using wheels that are too small for the load can also create safety risks, including unstable movement or sudden failure.

5. How can I tell if my caster wheel diameter is too small?

If the equipment is difficult to start moving, gets stuck on small obstacles, or requires excessive force to push, the caster wheel diameter may be too small. Visible wheel damage, uneven rolling, or frequent caster replacements are also signs that a larger wheel size may be needed.

Email US

Email US

Hours

Hours

Visit Our Showroom

Visit Our Showroom