How to Properly Install and Secure Stem Casters

Apr 29th 2025

Whether outfitting heavy industrial equipment, making a hospital bed more mobile, or adding wheels to a display rack, stem casters are an excellent solution for improving mobility. From manufacturing floors to healthcare facilities and retail environments, casters simplify everyday tasks by allowing you to move items easily.

In this comprehensive guide, I’ll cover everything you need to know about stem casters: how to select the right ones for your needs, the tools you’ll need for installation, and step-by-step instructions for securely attaching them.

What Are Stem Casters?

Stem casters are a type of caster wheel designed for easy installation on furniture, carts, and equipment. They feature a vertical rod, or "stem," that inserts into a pre-drilled hole, socket, or tube, creating a secure connection. This design ensures stability while allowing smooth movement across various surfaces. Stem casters are available in multiple styles, including threaded, grip ring, and grip neck stems, each suited for different mounting applications. They are commonly used in office chairs, medical equipment, and retail displays. With swivel, locking, or rigid configuration options, stem casters provide mobility while maintaining safety and durability.

Common Applications

Stem casters are used in a variety of industries:

Manufacturing

Heavy-duty stem casters play a crucial role in industrial environments by enabling the smooth and efficient movement of heavy machinery, workstations, and production equipment. These casters are designed to withstand substantial loads, vibrations, and continuous operation, ensuring durability and reliability. With features such as reinforced wheels, precision bearings, and high-weight capacity, they provide stability and ease of transport on factory floors. Many heavy-duty casters also have locking mechanisms to keep equipment in place during operation.

Warehousing and Logistics

Warehouses and logistics centers rely on stem casters to improve workflow efficiency by facilitating the movement of carts, pallets, and storage racks. These casters allow employees to transport goods quickly and safely, reducing strain and increasing productivity. Designed for high-impact use, they often feature durable materials such as polyurethane or steel to withstand heavy loads and frequent movement. Swivel and locking options provide precise maneuverability in narrow aisles and crowded storage areas.

Healthcare

In hospitals and medical facilities, stem casters are essential for ensuring smooth mobility of critical equipment, such as hospital beds, IV poles, and medical trolleys. These casters are designed for quiet operation, helping to maintain a peaceful environment for patients. Many healthcare casters feature non-marking, antimicrobial wheels to reduce the spread of bacteria and protect flooring. Swivel and braking mechanisms allow for precise movement and stability, which is crucial in emergencies.

Retail and Hospitality

Retail and hospitality businesses depend on stem casters to improve mobility in merchandise displays, food service carts, and shelving units. These casters make it easy to rearrange store layouts, transport heavy products, and create flexible retail spaces. In restaurants and hotels, stem casters improve service efficiency by allowing carts and racks to move effortlessly between kitchen, dining, and storage areas. Many hospitality casters are designed with smooth-rolling, non-marking wheels to protect floors and reduce noise.

Why Choose Stem Casters?

Stem casters are ideal when:

- Stem casters are designed to fit into these mounting points, providing a secure and stable connection without requiring additional modifications. This makes installation quick and easy and ensures compatibility with a wide range of furniture and equipment.

- Unlike plate casters, which require a larger mounting surface, stem casters have a discreet design that keeps the focus on the furniture’s aesthetics. This makes them ideal for modern and stylish applications where appearance is just as important as functionality.

- Stem casters allow furniture and equipment to move effortlessly, making them ideal for dynamic spaces such as offices, workshops, and retail stores. Options like swivel and locking mechanisms offer smooth movement while maintaining stability when needed.

How Do Stem Casters Work?

Stem casters function by inserting the stem into a hole or socket on the object you’re mobilizing. The way the caster is secured depends on the type of stem:

- Grip Ring Stem Casters: These have a rubber or metal ring that compresses when inserted into the hole, locking the caster into place.

- Threaded Stem Casters: The stem has threading that screws into a pre-threaded hole or a threaded caster insert, providing a tight fit.

- Expanding Stem Casters: These are designed to fit into hollow tubing or irregularly shaped sockets. Once inserted, the stem expands as you tighten a nut or screw, creating a snug, secure fit.

This simple design allows for easy installation, replacement, and maintenance, making stem casters a versatile choice for many applications.

Choosing the Right Stem Caster

Selecting the proper stem caster ensures smooth operation, stability, and durability. Consider these factors when making your choice:

Types of Stem Casters

- Grip Ring Stem Casters: Best for lightweight applications like office chairs, carts, and racks.

- Threaded Stem Casters: Ideal for furniture or equipment with threaded sockets or when combined with threaded inserts for wood.

- Expanding Stem Casters: Perfect for hollow tubing, standard in medical or industrial equipment.

Weight Capacity Considerations

Determine the combined weight of the object and its contents, and divide it by the number of casters you plan to use. For example, if a cart weighs 200 lbs. and you’re using four casters, each caster must support at least 50 lbs. Always choose casters with a slightly higher weight capacity than required for added safety.

Material and Surface Compatibility

The type of floor or surface your caster will roll on impacts your choice of wheel material:

- Hard Rubber or Polyurethane Wheels are suitable for indoor surfaces like wood, tile, or linoleum and offer smooth and quiet rolling.

- Metal or Steel Wheels: Best for heavy-duty industrial environments with concrete or rough surfaces.

- Non-Marking Wheels: Ideal for healthcare or retail spaces where floor protection is critical.

Tools and Materials You’ll Need

Before starting your caster wheels installation, gather the following tools and materials:

- Stem Casters (appropriate type for your application)

- Drill and Drill Bits: These create holes if none exist.

- Screwdriver: For tightening screws on threaded or expanding stems.

- Rubber Mallet: This is used to gently tap the grip ring stems into place.

- Threaded Caster Inserts: To provide a secure base for threaded stems, especially in wood.

- Measuring Tape: To ensure accurate alignment and placement.

- Wrench or Adjustable Spanner: For tightening nuts on expanding or threaded stems.

Having everything on hand before you begin will save you time and frustration.

How to Install Casters with Stems?

Installing casters may seem daunting, but it’s a straightforward process. Here’s how I approach it:

Step-by-Step Instructions

1. Evaluate Your Furniture or Equipment:

Look for pre-existing holes or sockets. If none are available, measure and drill holes where needed.

2. Select the Appropriate Caster Stem Type:

-

-

- Use grip stems for sockets.

- Use threaded stems for pre-threaded holes or with threaded inserts.

- Use expanding stems for hollow tubing.

-

3. Prepare the Surface:

Clean the mounting area to ensure a secure fit. If installed on wood, consider using threaded caster inserts to reinforce the holes.

4. Attach the Casters:

-

- Grip Ring Stem Casters: Push the stem into the socket and tap gently with a mallet until the ring compresses and locks in place.

- Threaded Stem Casters: Screw the caster into the threaded hole or insert it using a wrench.

- Expanding Stem Casters: Insert the stem, then tighten the nut or screw to develop the stem and lock it securely.

5. Check for Stability:

After installation, test each caster by applying light pressure and flatting the equipment or furniture. Ensure the caster is securely fitted in its socket and does not wobble or detach. Smooth and consistent rolling indicates proper installation, while any instability may require adjustments or a tighter fit.

How to Install Grip Ring Stem Casters on Wood

Here’s a step-by-step guide for wooden furniture:

- Drill a hole slightly smaller than the grip stem’s diameter.

- A threaded caster is inserted into the hole for added strength.

- Push the grip ring stem into the hole.

- Tap the caster with a rubber mallet to compress the ring and securely lock the stem.

How to Use Expanding Stem Casters

Expanding stem casters are excellent for hollow tubing, such as in medical or industrial equipment.

- Insert the stem into the hollow tubing or opening.

- Tighten the nut or screw at the base of the stem. As the screw tightens, the stem expands to fill the hole, creating a snug fit.

- Confirm that the caster is secure by rolling it back and forth.

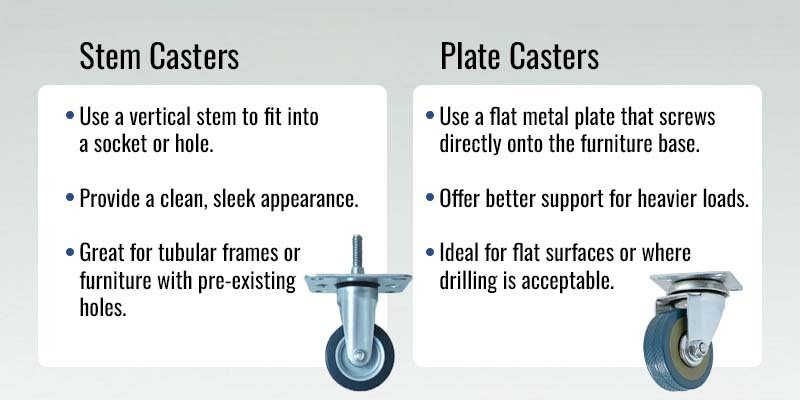

What is the Difference Between Stem and Plate Casters?

While both stem and plate casters serve the same essential function—adding mobility to furniture or equipment—they differ in their mounting methods:

- Stem Casters:

- Use a vertical stem to fit into a socket or hole.

- Provide a clean, sleek appearance.

- Great for tubular frames or furniture with pre-existing holes.

- Plate Casters:

- Use a flat metal plate that screws directly onto the furniture base.

- Offer better support for heavier loads.

- It is ideal for flat surfaces or where drilling is acceptable.

Tips for Attaching Caster Wheels Securely

Here are some best practices to ensure your casters are securely attached:

- Threaded inserts strengthen mounting points in wood or other soft materials.

- Double-check the weight capacity of your casters to avoid overloading.

- Add locking casters to keep your equipment stationary when needed.

- Periodically inspect the casters for wear or loose fittings.

FAQs

1. How to Install Casters with Stems?

The installation process depends on the type of stem (grip, threaded, or expanding). Push-in casters like grip stems are pressed into a socket, while threaded casters screw into a hole or insert. Expanding casters use a tightening mechanism to secure the stem.

2. How Do Stem Casters Work?

Stem casters rely on a vertical stem to attach to furniture or equipment. The type of stem determines how the caster is secured—via compression, threading, or expansion.

3. How do you install grip ring stem casters on wood?

Drill a hole slightly smaller than the grip stem, insert a caster insert for extra reinforcement, and push the stem into the hole until secure.

4. How to Use Expanding Stem Casters?

Insert the expanding stem into the hollow tube or socket, then tighten the screw to expand the stem. This locks the caster securely in place.

5. What is the Difference Between Stem and Plate Casters?

Stem casters attach via a vertical rod, while plate casters are mounted using a flat plate that screws onto the furniture base.

Wrapping Up

Stem casters are a versatile and practical solution for improving mobility in your equipment or furniture. By following this guide, you can select the perfect casters for your needs and attach them securely.

Need help finding the right casters? Contact Atlanta Caster today for expert advice and a wide selection of high-quality caster wheels. Don’t wait—let’s get rolling!

Email US

Email US

Hours

Hours

Visit Our Showroom

Visit Our Showroom