How to Quiet Down Noisy Carts: Wheel Material & Bearing Tips

Apr 22nd 2025

You’re rolling a cart through a hospital hallway, a quiet office, or a laboratory—and it sounds like a shopping cart with square wheels. The clatter isn’t just annoying- it can disrupt patients, distract workers, and affect the overall atmosphere of your facility. In professional settings where silence and smooth operation are critical, reducing cart noise is more than a preference—it’s necessary.

Understanding casters and how their components affect performance is the first step toward a quieter environment. Casters are the wheeled mechanisms that allow carts, equipment, and furniture to roll. The noise they generate comes from several factors, including the wheel material and bearing type. Choosing the correct combination can make the difference between a cart that glides quietly and one that echoes down the hall.

This guide shares the best options for quiet caster wheels and noiseless casters, including wheel materials designed for low noise, bearing types that minimize vibration, and how to install or replace casters effectively. Whether you're in healthcare, education, or light industrial work, the right caster can help keep your workspace calm and productive. Let’s break down the options for quieter, more efficient mobility.

What Are Casters and Why Do They Get Noisy?

Casters are wheeled components mounted to the base of carts, equipment, or furniture to enable smooth and controlled movement. They are usually found in commercial, industrial, and institutional settings where mobility and maneuverability are essential.

A standard caster is made up of four main parts:

- The wheel rolls along the floor.

- The yoke (also called the fork) holds the wheel in place.

- The mounting plate or stem connects the caster to the object it supports.

- The bearings allow the wheel or swivel section to rotate freely and smoothly.

These parts work together to reduce the effort required to move heavy loads.

Casters come in various sizes, materials, and configurations depending on the application, and their performance can be affected by how and where they are used. While most casters are designed for function and load-bearing, not all are built to reduce noise. Excess noise from carts or equipment can be distracting or even disruptive in environments like hospitals, labs, or offices. Choosing quiet caster wheels made from appropriate materials and with quality bearings helps minimize this issue. Understanding casters and their operation is the first step in selecting the right solution for quieter, more efficient movement.

Why Casters Get Noisy

Caster noise usually comes from vibration, worn components, or low-quality materials. Hard wheels on hard flooring can generate excessive sound. Dry, damaged, or poorly constructed bearings can also create grinding or rattling noises. Over time, casters may become unbalanced, leading to uneven rolling and vibration that amplifies noise.

Types of Casters

There are three common types:

- Rolling Casters: A general term that includes both swivel and fixed types.

- Fixed Casters: Roll in a straight line- do not rotate side to side.

- Swivel Casters: Rotate 360 degrees, offering more excellent maneuverability.

Choosing the right type is essential for both function and noise reduction.

When Noise Is a Problem

Excess noise can disrupt workflow, affect patient care, or create a poor customer experience in environments like laboratories, hospitals, offices, and restaurants. Selecting quiet caster wheels with soft rubber or polyurethane and high-quality bearings can significantly reduce noise in these sensitive settings. Knowing what casters are and their role in mobility helps select quieter, longer-lasting solutions.

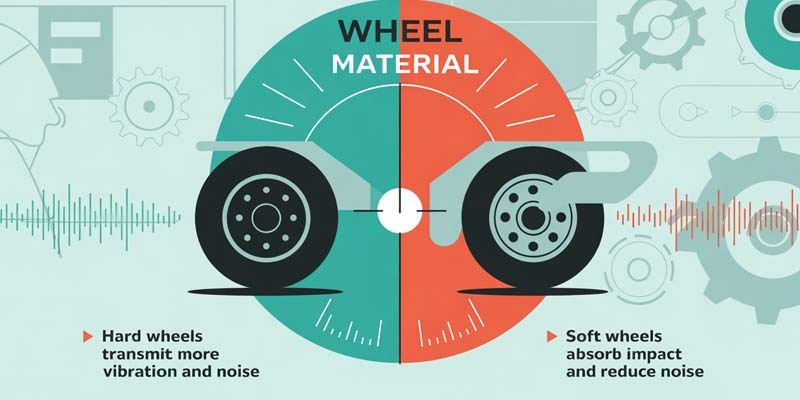

The Role of Wheel Material in Reducing Noise

Wheel material help determine how loud or quiet a caster will be in use. Hard wheels transmit more vibration and noise, especially on hard surfaces like tile or concrete. In contrast, soft caster wheels absorb more impact, helping reduce both rolling noise and vibration. The right material is key when aiming for quiet caster wheels in noise-sensitive environments.

Soft Caster Wheels

Soft caster wheels are ideal for applications where noise reduction and floor protection are critical. These wheels are often made of rubber, polyurethane, or thermoplastic rubber and offer several key advantages:

- Shock Absorption: Soft wheels compress slightly under load, absorbing vibrations and reducing noise from rolling on uneven or hard surfaces.

- Quieter Operation: Less vibration and friction translate to significantly quieter wheels in motion, especially in quiet spaces like hospitals or labs.

- Floor Protection: Soft materials such as tile, wood, or vinyl prevent scuffing or damage to delicate floors.

- Improved Traction: These wheels grip better on smooth surfaces, reducing slippage and adding control.

- Versatility: Commonly used in healthcare, hospitality, and office settings where low noise and maneuverability are essential.

Polyurethane vs. Rubber

Polyurethane wheels are highly durable and have high load-bearing capacity. They provide moderate noise reduction and resist wear, chemicals, and abrasion. These are often used in industrial or commercial applications where quiet operation is essential, but heavier loads must still be handled efficiently. On the other hand, rubber wheels offer superior sound dampening and shock absorption. They are ideal for lightweight carts in schools, hospitals, and offices. However, the rubber wears faster under heavy loads and can leave marks on certain floor types unless labeled non-marking caster wheels.

Thermoplastic Rubber (TPR) vs. Nylon

TPR combines rubber's resilience with plastic's strength, offering low noise, smooth rolling, and floor protection. It’s also resistant to chemicals and liquids, making it ideal for labs, healthcare, and food service. In contrast, nylon wheels are tough and durable but loud when rolling on hard surfaces. Nylon is better suited for rugged environments like warehouses, where floor noise is less of a concern.

When to Choose Non-Marking Caster Wheels for Quieter Performance

Nonmarking caster wheels are essential in environments where clean floors and low noise are priorities. These wheels are made from soft rubber, polyurethane, or TPR, which do not leave scuffs or residue. They're often selected for hospitals, laboratories, schools, and offices where maintaining a quiet and clean appearance is essential. These quiet caster wheels also prevent surface damage, extending the life of your flooring.

Material Impact on Surfaces

Hard wheels like nylon or steel create more noise and damage surfaces such as tile, hardwood, or epoxy-coated concrete—their lack of cushioning leads to increased vibration and rolling noise. In contrast, soft caster wheels made of rubber or TPR roll more quietly and protect the floor by absorbing impact. For indoor environments with delicate flooring, quiet wheels made from soft materials are the better long-term solution.

Choosing the Right Bearing Type for Noise Reduction

The wheel material is only half the equation when selecting quiet caster wheels or noiseless casters. The bearing type inside the caster also plays a key role in reducing noise and improving movement. Bearings affect how smoothly a wheel rolls, how much load it can carry, and how quietly it operates. Choosing the right bearing type for your application helps ensure long-term, low-noise performance in sensitive environments.

Plain Bearings

Plain bearings, or sleeve bearings, are the most basic option. They consist of a simple bushing between the wheel and axle, allowing rotation through surface contact. These are cost-effective and have no moving parts, making them low-maintenance. However, they are not ideal for noise-sensitive settings, as they can produce friction noise under load. While durable in light-duty uses, they lack the smoothness required for truly noiseless casters.

Delrin Bearings

Delrin bearings are made from low-friction acetal resin and are self-lubricating. They are known for being lightweight, corrosion-resistant, and quieter than plain bearings. Delrin bearings offer a good balance of durability and reduced noise. They are ideal for light—to medium-duty applications and are generally used in environments where moisture or chemicals are present. These bearings help create smoother, quieter motion in carts used in labs, offices, or medical facilities.

Roller Bearings

Roller bearings use cylindrical rollers to reduce friction between the wheel and axle. They can handle heavier loads than plain or Delrin bearings but tend to generate more noise due to increased metal contact. While they provide improved durability and load capacity, they are not typically used in quiet caster wheels for noise-sensitive environments. They're better suited for industrial settings where silent operation is less critical.

Precision Ball Bearings

Precision ball bearings are engineered for smooth, silent performance and are the preferred option in noiseless casters. They use high-quality, sealed ball bearings that minimize friction and vibration, resulting in near-silent movement. These bearings support moderate to heavy loads and are excellent for medical carts, lab equipment, and office furniture where low noise and easy maneuverability are essential. Precision ball bearings are more expensive but provide superior quiet and long-term performance.

How Bearings Affect Smoothness, Load Capacity, and Quiet Operation

The type of bearing inside a caster significantly influences its performance. Bearings minimize friction between the wheel and axle, allowing smoother and quieter motion. Plain bearings offer simplicity but may lack smoothness. Delrin bearings offer moderate quietness and chemical resistance. Roller bearings increase load capacity but can add noise. Precision ball bearings deliver the best load handling and noise reduction results, making them ideal for quiet caster wheels in sensitive environments.

Best Bearing Types for Noise-Sensitive Environments

For applications requiring noiseless casters, the following bearing types are most effective:

- Precision Ball Bearings – Best for smooth, quiet rolling and long-lasting performance.

- Delrin Bearings – Quiet, corrosion-resistant, and ideal for light to medium loads.

- Sealed Bearings – Prevent dust and moisture buildup, reducing maintenance and noise.

- Dual Ball Bearings – Provide better stability and noise control for frequent use.

Maintenance Tips for Keeping Bearings Quiet

Regular maintenance can extend caster life and reduce noise levels.

- Inspect casters regularly for signs of wear or damage.

- Clean bearings using a dry cloth to remove dirt and debris.

- Lubricate moving parts with a light-duty lubricant as recommended by the manufacturer.

- Tighten loose components to prevent rattling or vibration.

- Replace worn bearings promptly to avoid excess friction and noise.

When and Why to Replace Casters

Regular rolling caster inspection is essential to maintaining a quiet and efficient workspace. Over time, even high-quality casters can wear down, leading to increased noise, reduced performance, and floor damage. Knowing when to replace them can prevent these issues and improve daily operations.

Worn-Out Treads

Excessively worn or cracked wheel treads are a common cause of noise. As the tread breaks down, the wheel loses its ability to absorb impact, increasing vibration and sound during use. Soft caster wheels that are flattened or have visible wear lines should be replaced immediately to restore quiet operation.

Flattened Wheels

Flat spots on wheels create uneven rolling, which causes a thumping sound with each rotation. This is especially noticeable on hard floors and indicates that the wheel no longer distributes weight evenly. Flattening often results from prolonged static loads or overuse.

Damaged Bearings

Bearings that grind, seize, or rattle during movement are no longer functioning correctly. Damaged bearings increase resistance and generate noise, reducing the effectiveness of quiet caster wheels. If lubrication no longer resolves the issue, replacement is necessary.

Benefits of Timely Replacing Casters

Replacing worn casters promptly offers several benefits:

- Improved Mobility: Smooth, reliable movement with minimal resistance.

- Quieter Operation: Restores the performance of quiet caster wheels in noise-sensitive environments.

- Protects Flooring: Prevents gouging, scuffing, or denting caused by worn or damaged wheels.

- Reduces Equipment Strain: Less vibration means less stress on carts and their contents.

- Improved Safety: Prevents tipping or instability caused by uneven rolling casters.

When choosing replacement casters, match the original specifications in size, bearing type, wheel material, and mounting style. This ensures proper fit, maintains performance, and avoids added noise or wear. Select the right caster for the specific application to maximize durability and comfort.

How to Install Casters Properly for a Quieter Ride

Installing casters correctly is essential to achieving smooth, quiet wheels and reducing long-term wear. Poor installation can lead to vibration, misalignment, squeaking, or wobbling. Follow these steps to ensure proper mounting:

- Clean the mounting surface before installation to ensure a flush fit.

- Align mounting holes accurately to prevent uneven pressure on the caster.

- Use the correct hardware—undersized bolts or screws can loosen over time.

- Tighten securely, but avoid over-torquing, which can damage the caster housing.

Plate vs. Stem Mounting:

- Plate Mounting: Offers better stability and is ideal for heavy loads. Ensure all bolts are evenly tightened to prevent shifting.

- Stem Mounting is often used for chairs or light-duty carts. Misaligned stems can cause the caster to tilt or squeak during use.

Proper installation is key to benefiting from quiet caster wheels in any application.

Tips for Reducing Vibration

To reduce vibration and extend the life of your quiet wheels:

- Use washers to create a snug, even fit, and reduce movement.

- Apply thread lockers to prevent bolts from loosening over time.

- Distribute weight evenly across all casters to avoid overloading one wheel.

- Choose soft caster wheels for added shock absorption.

- Inspect regularly to ensure tight fittings and balanced load support.

Tools Needed and Safety Precautions

Essential tools for installation include a wrench, screwdriver, drill, level, and measuring tape. Always disconnect equipment from power, use protective gloves and eyewear when drilling or lifting, and understand how to install casters safely and accurately to ensure long-lasting, quiet caster wheel performance.

Case Studies & Real-World Applications

Choosing the right casters can make a measurable difference in noise levels, floor protection, and ease of movement. The following real-world examples show how switching to quiet caster wheels, soft caster wheels, or noiseless casters has improved operations across different industries.

Warehouse

A regional distribution center replaced traditional metal rolling casters with soft caster wheels on their packing carts. Noise complaints dropped significantly, and workers reported less fatigue due to smoother movement. The maintenance lead shared, “The switch cut floor noise by half and improved morale during long shifts.”

Hospital

An extensive hospital system upgraded its medical carts with nonmarking caster wheels made of thermoplastic rubber. The result was quieter hallways and improved patient comfort. “We no longer get complaints about nighttime noise from rolling carts,” said a procurement manager. “It’s been a major improvement in our patient care environment.”

Office

An administrative building replaced older carts with noiseless casters featuring Delrin bearings. These quiet wheels eliminated squeaks on laminate floors and reduced vibration. “The difference was immediate,” the facility manager noted. “Our staff moves supplies without disturbing nearby meetings or calls—it’s made the office environment more professional and pleasant.”

Expert Tips to Keep Rolling Casters Quiet Over Time

Maintaining rolling casters is essential for preserving quiet, smooth operation—especially in noise-sensitive environments. Start with a regular maintenance routine. Clean wheel treads and caster housings to remove debris that can cause rattling or vibration. Apply lubricant to the wheel and swivel bearing types as recommended, and tighten all mounting hardware to prevent movement that leads to squeaking.

Avoid exceeding the caster’s rated weight limit. Overloaded wheels can flatten, increase friction, and generate more noise. Always match your quiet caster wheels to the load requirements of your application.

Proper storage also plays a role. Keep carts and equipment on level surfaces and avoid storing them under heavy loads for extended periods, which can create flat spots.

Finally, monitor usage and rotate wheels if uneven wear is noticed. Bearings should be re-lubricated every few months or more often in high-use environments to keep rolling casters operating quietly and efficiently.

Final Thoughts

Reducing cart noise comes down to the right combination of materials, bearing types, and ongoing maintenance. Choosing quiet caster wheels made from soft, non-marking materials and high-quality bearings results in smoother, quieter performance. Regular upkeep further extends their lifespan and minimizes disruptions in sensitive environments.

Take time to evaluate your current setup—if you're hearing squeaks, vibration, or thumping, it may be time for replacement casters or an upgrade to noiseless casters.

Need help finding the right solution? Contact Atlanta Caster for expert guidance on the best wheels, bearings, and caster replacements for your needs.

FAQ

1. What are the quietest types of caster wheels?

The quietest caster wheels are typically made from soft polyurethane or thermoplastic rubber (TPR). These materials absorb shock and reduce vibration, making them ideal for noise-sensitive environments. Paired with precision or Delrin bearings, these quiet caster wheels offer smooth, silent operation on hard or uneven surfaces.

2. Can I make my current cart quieter without replacing the wheels?

You can reduce noise by cleaning and lubricating the bearings, tightening all mounting hardware, and ensuring the cart is not overloaded. Adding washers or shock-absorbing pads can also help. While these steps help, replacing worn or hard wheels with quiet caster wheels offers the most effective noise reduction.

3. Which bearing types are best for hospital or office carts?

Precision ball bearings and Delrin bearings are best for hospital and office carts. They provide smooth, silent movement and minimize friction. These bearing types are ideal for noiseless casters in environments where low noise, easy maneuverability, and reliability are critical, especially on tile or other hard flooring surfaces.

4. Are nonmarking caster wheels also noise-reducing?

Yes, nonmarking caster wheels often reduce noise as well. Made from soft materials like rubber or TPR, they roll quietly and prevent floor scuffs or marks. These wheels are commonly used in healthcare and office settings where cleanliness and low noise are critical priorities.

5. How do I know when it’s time to install replacement casters?

Replace casters when you notice increased noise, flat spots, cracked treads, or wobbly movement. Damaged or seized bearings are also a sign. If your cart no longer rolls smoothly or starts causing flood damage, it's time to install replacement casters to restore performance and quiet operation.

Email US

Email US

Hours

Hours

Visit Our Showroom

Visit Our Showroom