Improving Safety and Efficiency: The Role of Casters in Preventing Workplace Injuries

Sep 30th 2025

Introduction

Workplace mobility is often taken for granted until equipment becomes difficult to move or fails altogether. In busy environments like hospitals, warehouses, and manufacturing plants, the small components that support movement play a critical role in protecting workers and keeping operations efficient. When carts, racks, or machinery are difficult to maneuver, the risk of workplace injuries rises sharply. Employees may strain themselves trying to push heavy loads, or accidents can occur when unstable equipment shifts unexpectedly.

At the center of these mobility challenges are casters and wheels. Far more than simple rolling parts, they determine how equipment moves, how much weight it carries, and how safe it is for employees to use every day. From industrial casters built for factories to ergonomic casters designed to reduce strain, the right choice can help avoid workplace injuries and improve productivity.

This article explores what casters are, their impact on safety, and how selecting the right design—whether

swivel casters, rigid casters, or heavy duty casters—directly affects worker protection and operational efficiency. By examining the different types of casters, maintenance practices, and industry-specific applications, facility managers and safety supervisors will gain a clear understanding of how such a small component can have such a large influence on both efficiency and well-being.

What Are Casters and Why They Matter in Workplace Safety?

To understand how mobility affects safety, it helps to start with the basics: what are casters? Casters are assemblies that combine a wheel with a mount, allowing equipment to roll instead of being dragged or lifted. Unlike simple wheels, casters can be configured in multiple ways—some designed to swivel, others fixed in place—giving them a unique advantage in material handling, healthcare, and retail settings.

When selecting casters and wheels, it’s important to consider both the type of mount and the wheel material. For example, swivel casters rotate 360 degrees, making it easier to maneuver hospital beds through tight corridors. On the other hand, rigid casters only roll in a straight line, providing stability for equipment that must stay aligned, such as warehouse racks or assembly line carts.

Safety becomes a concern when the wrong caster is chosen or when existing wheel casters wear out. An overloaded cart with poor-quality casters is harder to push, increases strain, and can tip unexpectedly. In high-paced industries where efficiency matters, these risks add up quickly.

The right caster selection—whether equipment casters in healthcare, commercial casters for retail displays, or casters heavy duty for industrial machinery—does more than keep equipment moving. It actively helps reduce accidents, protect workers, and keep daily operations running smoothly.

The Link Between Poor Mobility and Workplace Injuries

Every year, thousands of employees suffer a workplace injury linked to poor ergonomics and unsafe equipment movement. In many cases, the root cause is not the worker’s mistake but the failure of mobility components like casters and wheels. When carts, beds, or racks don’t roll smoothly, workers must apply extra force to push or pull them. Over time, this repeated strain can lead to musculoskeletal disorders, one of the most common sources of workplace injuries.

Another danger comes from unstable or mismatched caster selection. For example, using small, light-duty casters on a heavy cart can cause wheels to break, shift, or jam. This can lead to tip-overs or sudden stops that injure staff. By contrast, the proper use of heavy duty casters or casters heavy duty ensures stability and prevents unpredictable movement.

The absence of locking casters also contributes to accidents. Imagine a medical device rolling unexpectedly while in use or a supply cart shifting on an inclined surface. Without locks, employees must constantly correct movement, increasing both fatigue and risk.

Even well-designed casters require upkeep. Neglecting caster maintenance allows dirt, rust, or damaged bearings to build up, which increases rolling resistance and makes accidents more likely.

Ultimately, investing in reliable industrial casters, ergonomic casters, and proper maintenance routines isn’t just about convenience. It’s a direct strategy to avoid workplace injuries by reducing strain, improving control, and ensuring equipment remains stable under all conditions.

Types of Casters and Their Role in Safety

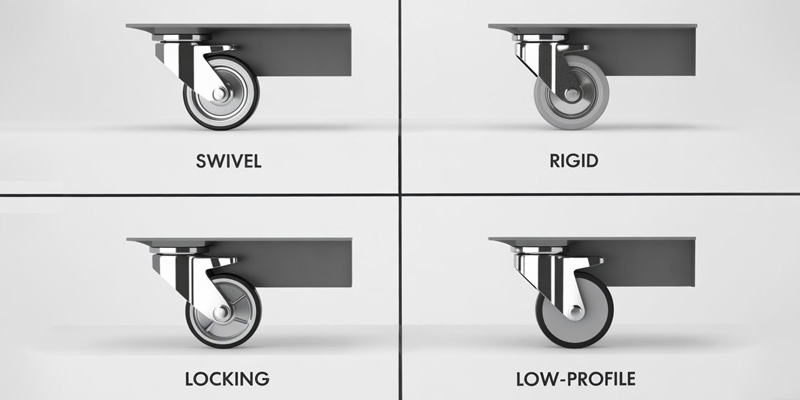

Not all casters are created equal. Different workplaces require different designs, and understanding the types of casters available is the first step toward safer, more efficient operations. Choosing the right configuration can mean the difference between smooth workflows and costly workplace injuries.

Swivel Casters

Swivel casters rotate 360 degrees, giving equipment maximum maneuverability. In hospitals, they allow staff to move patient beds or IV carts through tight corridors without lifting or dragging. In retail, they make displays easy to reposition. Their flexibility reduces strain, but in high-load environments, they should often be paired with rigid wheels for stability.

Rigid Casters

Rigid casters are fixed in one direction, rolling only forward and backward. While they don’t provide turning flexibility, they deliver straight-line stability, making them ideal for warehouse racks, assembly lines, and factory equipment. Many facilities combine swivel casters and rigid models on the same cart to balance control with maneuverability.

Locking Casters

When equipment must remain stationary, locking casters provide security. Common in healthcare, locking designs prevent carts, beds, or devices from rolling unexpectedly, reducing the risk of falls or impact injuries. In industrial settings, they keep heavy machinery stable during operation.

Low Profile Casters

Low profile casters are designed for applications where height clearance is limited, such as server racks, electronic cabinets, or specialized medical devices. Their compact design lowers the center of gravity, increasing stability and reducing tip-over risk. While not suited for rough surfaces, they play a critical safety role in controlled environments.

By considering these different types of casters—and matching them to the right application—buyers can reduce equipment strain, protect workers, and prevent unnecessary workplace injuries.

Industrial Casters and Heavy Duty Solutions

When loads are large and the stakes are high, industrial casters become indispensable. Designed for demanding environments such as factories, warehouses, and distribution centers, they support heavy machinery, pallet carts, and assembly equipment that would be impossible to move otherwise. Unlike lighter options, these casters are built with reinforced frames, larger wheels, and materials that withstand constant stress.

The primary advantage of heavy duty casters is their ability to handle thousands of pounds without compromising safety. For example, in a warehouse, carts equipped with heavy duty casters can move stacked pallets with ease, reducing the need for forklifts in tight spaces. This not only boosts efficiency but also reduces accident risks caused by improper manual handling.

Healthcare and laboratory settings also rely on rigid casters or rigid steel casters when equipment must remain stable during operation but still be movable when necessary. By choosing higher-capacity designs, facilities avoid wheel collapse, which could cause both equipment damage and a potential workplace injury.

For businesses in retail or hospitality, commercial casters fill a similar role but with a balance of strength and aesthetics. These casters support display racks, rolling service carts, and storage units while maintaining a professional appearance.

Ultimately, the decision to use industrial casters or heavy duty casters is about more than just moving weight. It is a proactive measure to avoid workplace injuries, reduce downtime, and extend the life of valuable equipment.

Ergonomic Casters: Protecting Workers from Strain

One of the most overlooked causes of workplace injuries is repetitive strain. Employees who spend hours pushing or pulling carts, beds, or racks often develop musculoskeletal disorders in the shoulders, back, and wrists. These injuries don’t happen overnight—they build gradually through years of small but excessive effort. This is where ergonomic casters make a measurable difference.

Unlike standard wheels, ergonomic casters are engineered to reduce rolling resistance. They use precision bearings, softer treads, or advanced wheel designs that minimize the force required to get equipment moving. For example, a supply cart equipped with caster wheels for carts that feature ergonomic design requires less push force, lowering the risk of fatigue and injury.

In healthcare, nurses benefit from beds and IV carts fitted with swivel casters and ergonomic features, allowing them to move patients safely without excessive strain. In warehouses, ergonomic wheels on equipment casters reduce the physical effort required to transport goods, especially over long distances.

The cost of upgrading to ergonomic designs is often offset by reduced injury claims and increased productivity. Facilities that prioritize worker safety find that ergonomic casters are not just accessories—they’re critical components in long-term injury prevention strategies. By choosing them, employers take a proactive step to avoid workplace injuries while keeping operations running smoothly.

Equipment Casters in Healthcare and Commercial Settings

The role of equipment casters extends far beyond warehouses. In healthcare facilities, mobility directly affects patient care and staff safety. Hospital beds, IV stands, and diagnostic machines rely on casters that roll smoothly, lock securely, and withstand constant cleaning. A poorly chosen or worn-out caster can lead to a workplace injury if equipment shifts unexpectedly during patient transport or medical procedures.

Healthcare environments often combine swivel casters for maneuverability with rigid casters for straight-line control. This balance ensures staff can move equipment through crowded hallways while maintaining stability when stationary. In high-demand areas such as emergency rooms, locking casters are essential to prevent rolling during treatment. Specialized low profile casters are also used for imaging devices and electronic cabinets where stability and clearance are critical.

Outside of healthcare, commercial casters support retail displays, rolling service carts, and storage units. These casters need to be strong yet discreet, blending functionality with aesthetics. For example, wheel casters on restaurant serving carts must be quiet, easy to maneuver, and safe for both staff and customers.

Whether in hospitals, labs, restaurants, or retail spaces, the right choice of casters and wheels directly impacts safety and efficiency. By selecting high-quality equipment casters and pairing them with regular caster maintenance, facilities ensure reliability, reduce downtime, and most importantly, help avoid workplace injuries caused by unstable or malfunctioning equipment.

Caster Maintenance: A Key Step in Preventing Workplace Injuries

Even the best industrial casters or ergonomic casters won’t perform safely if they aren’t properly maintained. Over time, debris builds up in bearings, wheels flatten under weight, and mounts loosen from constant use. Neglecting caster maintenance not only reduces efficiency but also increases the risk of a workplace injury. A cart that suddenly veers off course or a hospital bed that won’t stay in place can create serious hazards.

Routine checks can extend the life of casters and wheels and keep staff safe. Facilities should adopt a preventive schedule that includes:

- Visual inspections: Look for cracks, flat spots, or excessive wear on wheel casters.

- Lubrication: Bearings and swivel joints on swivel casters need regular oiling to reduce resistance.

- Tightening mounts: Loose plates or stems on rigid casters compromise stability and lead to accidents.

- Cleaning: Dirt and string wrapped around low profile casters or locking casters can prevent smooth rolling or proper locking.

Healthcare and warehouse environments, where casters move constantly, benefit most from scheduled upkeep. Replacing worn wheels with casters heavy duty or commercial casters ensures equipment can handle daily stress without sudden failure.

By prioritizing caster maintenance, organizations reduce downtime, extend equipment life, and most importantly, help avoid workplace injuries. A small investment in regular care pays off in lower injury claims, safer staff, and more efficient operations.

Balancing Safety and Efficiency with the Right Caster Choice

Selecting the right caster is not just about finding a wheel that fits—it’s about understanding the impact of that decision on safety, efficiency, and long-term cost. Every facility must weigh trade-offs between maneuverability, load capacity, and ergonomics.

For example, swivel casters provide excellent maneuverability but can cause drift when moving heavy equipment in straight lines. Pairing them with rigid casters helps maintain directional control while preserving flexibility. Similarly, low profile casters are perfect for equipment with height restrictions, but they may struggle on uneven surfaces. In these cases, a combination of caster types ensures both safety and function.

Cost is another consideration. Lower-cost wheels may seem appealing, but without the durability of heavy duty casters, they wear down quickly, leading to higher replacement rates and a greater chance of workplace injury. On the other hand, investing in ergonomic casters may reduce strain on workers, lowering injury claims and improving overall productivity.

Atlanta Caster’s catalog makes it easier for buyers to evaluate these trade-offs with categories like equipment casters, commercial casters, and a wide range of casters and wheels by mount, size, and material. By considering not just upfront price but also safety and efficiency impacts, organizations can make informed decisions that benefit both workers and operations.

FAQs

1. What are casters and wheels used for in the workplace?

Casters and wheels are used to make equipment mobile, from hospital beds to warehouse carts. By reducing friction, they allow staff to move heavy loads safely. Choosing the right option—such as industrial casters, commercial casters, or ergonomic casters—helps improve efficiency and prevents strain-related workplace injuries.

2. How do swivel casters and rigid casters improve safety?

Swivel casters provide maneuverability, making it easier to navigate tight spaces, while rigid casters ensure straight-line stability for heavy or long loads. Many facilities use a mix of both to balance control and efficiency. This combination reduces accidents, helping to avoid workplace injuries caused by instability or poor handling.

3. What are heavy duty casters best for?

Heavy duty casters or casters heavy duty are designed for industrial environments where equipment must carry thousands of pounds. They are ideal for warehouses, factories, and manufacturing lines. Their durability reduces downtime and prevents wheel failure, which could otherwise result in damaged equipment or a workplace injury during transport.

4. Are ergonomic casters worth the investment for preventing workplace injuries?

Yes. Ergonomic casters reduce rolling resistance, making it easier for employees to push or pull carts and beds. This prevents repetitive strain injuries and improves productivity. Facilities using caster wheels for carts with ergonomic designs often see fewer workplace injuries and better long-term savings on injury-related costs.

5. How often should caster maintenance be performed?

Routine caster maintenance is essential for safety. Facilities with constant mobility—such as hospitals or warehouses—should inspect wheel casters monthly. Checks should include cleaning, lubricating swivel casters, tightening mounts, and replacing worn-out parts. Regular care helps equipment run smoothly and reduces the risk of accidents or a costly workplace injury.

6. Do low profile casters compromise stability?

Not at all. Low profile casters are designed to lower the center of gravity, making equipment more stable. They’re often used in electronics, medical imaging, or storage cabinets. While they may not perform well on uneven surfaces, they provide excellent safety and efficiency in controlled indoor environments.

7. When should locking casters be used for equipment?

Locking casters should be used whenever stability is critical, such as on hospital beds, lab equipment, or carts on sloped floors. Locks prevent unexpected movement that could injure staff or patients. Adding locks is one of the simplest ways to avoid workplace injuries while ensuring safety during use.

8. What’s the difference between commercial casters and industrial casters?

Commercial casters are often used for lighter applications like retail displays, service carts, or office equipment. Industrial casters, on the other hand, are built for heavy loads, constant use, and harsh environments. Both play an important role in mobility, but choosing the right one reduces accidents and improves efficiency.

Wrapping Up

The right caster choice is about more than keeping equipment mobile—it’s about protecting workers, reducing downtime, and ensuring smooth operations. From swivel casters that improve maneuverability in tight spaces to rigid casters that provide stability for heavy loads, each design plays a role in preventing workplace injuries. Options like ergonomic casters, low profile casters, and locking casters further enhance safety by addressing specific challenges across healthcare, manufacturing, retail, and warehousing.

Facilities that neglect caster quality or skip regular caster maintenance often face higher replacement costs and greater risks of accidents. On the other hand, investing in reliable industrial casters, heavy duty casters, and well-chosen equipment casters leads to safer environments, better efficiency, and long-term savings.

If your goal is to avoid workplace injuries while keeping staff productive, it starts with choosing the right caster solution.

Explore Atlanta Caster’s full range of products to improve safety and efficiency in your facility today.

Email US

Email US

Hours

Hours

Visit Our Showroom

Visit Our Showroom