Nylon vs. Polyurethane vs. Pneumatic Casters: Which Performs Better in Industrial Settings?

Sep 17th 2025

When it comes to moving equipment, carts, or heavy loads in a facility, the role of caster wheels is often underestimated. Many professionals only notice them when they fail — slowing down operations, damaging floors, or creating safety hazards. But selecting the right caster material from the start can have a significant impact on performance, efficiency, and overall cost of ownership.

So, what is a caster wheel exactly? In simple terms, it’s a wheel mounted inside a frame (the “caster”) that allows objects to be moved with less effort. Depending on the design, some casters swivel while others stay fixed. The bigger question for many facility managers and engineers is: what are caster wheels made of, and which material offers the most benefits in an industrial environment?

Three of the most common options in today’s marketplace are nylon casters, polyurethane casters, and pneumatic casters. Each material brings unique advantages and limitations. Nylon provides strength and durability, polyurethane offers a balance of floor protection and ergonomics, and pneumatic wheels deliver cushioning for rough terrain.

In this guide, we’ll break down the differences, compare real-world applications, and help you decide which solution works best for your industrial casters needs.

Understanding the Basics of Industrial Casters

Types of Casters Used in Industrial Settings

Before comparing materials, it’s important to understand the different types of casters available. At the most basic level, casters are divided into two main groups: rigid and swivel. Rigid casters keep the wheel fixed in a straight line, making them ideal for stability and long, straight runs. Swivel casters, on the other hand, rotate 360 degrees, giving workers the ability to maneuver heavy carts or machinery around corners with ease.

In industrial environments, variations of these core designs are widely used. Locking casters add braking mechanisms for safety. Ergonomic designs reduce the push and pull force required from employees. Specialized versions like nylon swivel casters are chosen when durability and smooth maneuverability are equally important. Facilities that handle extreme weight loads often turn to caster wheels heavy duty, which are engineered to support thousands of pounds without compromising safety.

Why Caster Material Matters in Performance

Casters are not a one-size-fits-all solution. The frame design determines how the wheel moves, but the material of the wheel itself determines how well it performs in specific conditions. For example, steel casters can carry incredible weight but may damage delicate floors. Rubber wheels absorb shocks but wear out quickly under heavy loads. This is why choosing between nylon casters, polyurethane casters, or pneumatic casters is such an important decision.

Material directly impacts:

- Load capacity (how much weight the caster can handle).

- Floor protection (preventing scratches or cracks).

- Noise levels in warehouses or production areas.

- Ergonomics — how much effort it takes to move equipment.

Ultimately, the best choice comes down to matching industrial casters and wheels to the working environment. A warehouse with epoxy floors, for instance, will have very different needs than a construction site with uneven outdoor surfaces. By understanding these basics, decision-makers can narrow down their options and focus on performance-driven solutions.

Nylon Casters: Lightweight Strength for Controlled Environments

What Are Nylon Casters?

Among the many wheel materials used in industrial settings, nylon casters stand out for their strength, low rolling resistance, and durability. Made from high-grade thermoplastic, these wheels are designed to withstand continuous use without warping or cracking. Unlike softer wheels, nylon resists water, chemicals, and many corrosive substances, making it a reliable choice for demanding environments such as chemical plants, food processing facilities, or cleanrooms.

One of the most common variations is the nylon swivel casters, which combine the strength of nylon with full 360-degree rotation. These casters allow workers to maneuver heavy carts in tight spaces while maintaining excellent load-bearing capabilities. When paired with a well-built rig, they become a dependable solution for moving heavy equipment with minimal effort.

Advantages of Nylon Swivel Casters in Industry

The biggest advantage of nylon casters is their load capacity. Pound for pound, nylon can handle more weight than many rubber or polyurethane wheels of the same size. This makes them particularly useful for caster wheels heavy duty applications, such as moving machine components, stacked pallets, or heavy racks.

Other notable benefits include:

- Durability in Harsh Environments – Nylon resists oils, greases, chemicals, and even extreme temperatures.

- Low Rolling Resistance – They move smoothly with less push force, reducing worker strain in production lines.

- Corrosion Resistance – Unlike steel wheels, nylon won’t rust when exposed to moisture.

- Cost-Effectiveness – Nylon often lasts longer than softer wheel types, reducing replacement frequency.

Limitations of Nylon Casters

Despite these advantages, nylon does have its limitations. The same hardness that gives nylon casters their strength can also be a drawback in certain environments:

- Noise on Hard Floors – Nylon can be loud when rolling across concrete or epoxy floors.

- Lack of Shock Absorption – Unlike pneumatic or polyurethane wheels, nylon provides little cushioning, which can be uncomfortable for operators and damaging to delicate loads.

- Floor Damage Risk – On softer surfaces, nylon may leave marks or cause wear over time.

Because of these limitations, nylon is not always the right choice for environments where floor protection, quiet operation, or operator comfort are top priorities.

Where Nylon Casters Perform Best

- Chemical Plants – Resistant to solvents and acids.

- Cold Storage Facilities – Handle freezing temperatures without cracking.

- Automotive and Heavy Manufacturing – Ideal for moving parts that demand caster wheels heavy duty performance.

- Warehousing with Smooth Concrete Floors – Their low rolling resistance ensures easy mobility.

In short, nylon swivel casters excel in environments where strength and resistance to harsh conditions outweigh the need for comfort or quiet operation. For industries focused on efficiency and heavy load handling, nylon remains one of the most dependable industrial casters solutions.

Polyurethane Casters: The Balance Between Durability and Floor Protection

What Are Polyurethane Casters?

In many industries, polyurethane casters are the go-to choice when a balance between durability, floor protection, and operator comfort is needed. Made by molding polyurethane around a metal or plastic core, these wheels combine the toughness of harder materials with a softer, resilient tread.

Often referred to as casters polyurethane, this category of wheels is highly versatile. They’re strong enough to carry substantial weight yet soft enough to minimize floor damage. Their unique composition makes them suitable for both light industrial carts and industrial casters and wheels designed for continuous heavy-duty use.

Benefits of Polyurethane Casters in Industrial Use

The popularity of polyurethane casters is no accident. Their advantages extend across many operational priorities:

- Floor Protection – Unlike steel or nylon, polyurethane prevents scratches, scuff marks, and cracking on delicate surfaces such as tile, epoxy, or coated concrete.

- Noise Reduction – Softer tread design reduces rolling noise, making them ideal for warehouses, hospitals, and 24/7 facilities where a quieter workspace is valued.

- Ergonomics – The natural cushioning effect reduces push and pull force, lowering the risk of repetitive strain injuries among workers.

- Chemical Resistance – Casters polyurethane resist oils, solvents, and many industrial chemicals, increasing longevity in production facilities.

- Durability – These wheels can withstand long-term use without chunking, cracking, or flat-spotting.

Because of these benefits, polyurethane is often seen as the “middle ground” between rigid nylon wheels and cushiony pneumatic options.

Challenges of Polyurethane Casters

While polyurethane casters perform well in most applications, they’re not perfect for every setting:

- Heat Sensitivity – Extreme high temperatures may cause polyurethane to soften or deform, limiting use in bakeries, foundries, or high-heat manufacturing.

- Heavy Loads – For the most demanding caster wheels heavy duty applications, nylon or steel casters may still be preferred because polyurethane, while strong, has weight limits.

- Cost – They can be more expensive upfront than rubber or nylon wheels, though the extended lifespan often justifies the investment.

Where Polyurethane Casters Perform Best

- Warehousing & Logistics – Smooth and quiet mobility on epoxy-coated or polished concrete floors.

- Healthcare & Food Processing – Floor protection combined with resistance to cleaning agents and sanitizers.

- Manufacturing – Perfect balance for medium- to heavy-duty equipment that requires both durability and operator comfort.

- Retail & Hospitality – Protect delicate flooring while maintaining an attractive, quiet presence.

Ultimately, casters polyurethane are ideal for facilities where both people and floors need protection. By offering durability, ergonomic benefits, and excellent floor care, they remain one of the most widely adopted industrial casters solutions today.

Pneumatic Casters: Cushioning for Rough Terrain and Outdoor Environments

What Are Pneumatic Casters?

When equipment or carts must travel across uneven ground, shock absorption becomes critical. That’s where pneumatic casters come in. These wheels are typically filled with air, similar to vehicle tires, or feature foam-filled alternatives. The design allows them to absorb impacts from bumps, cracks, or rough outdoor terrain.

To understand their purpose, it helps to look at pneumatic wheels meaning. Simply put, “pneumatic” refers to wheels that use air pressure to provide cushioning. This makes them unique compared to solid wheels like nylon casters or polyurethane casters, which provide less flexibility on uneven surfaces.

Benefits of Heavy Duty Pneumatic Casters

For industries operating outdoors or in rough conditions, heavy duty pneumatic casters offer unmatched versatility:

- Shock Absorption – The air-filled design reduces vibration and impact, protecting both the load and the operator.

- Operator Comfort – Reduced jarring motion makes moving carts easier on workers, especially over long distances.

- Traction – Heavy duty pneumatic tire casters provide superior grip on gravel, asphalt, or unfinished surfaces.

- Load Protection – Sensitive equipment or fragile goods are less likely to be damaged during transport.

Because of these strengths, pneumatic options are frequently chosen in construction sites, outdoor warehouses, and distribution hubs where surfaces are far from smooth.

Drawbacks of Pneumatic Casters

Despite their benefits, pneumatic casters are not without challenges:

- Maintenance – They require routine air pressure checks. If ignored, underinflation or punctures can lead to downtime.

- Lower Weight Capacity – Compared to caster wheels heavy duty made from nylon or polyurethane, pneumatic wheels carry less weight safely.

- Space Requirements – Their larger size may not fit all equipment designs.

For this reason, many businesses restrict their use of pneumatic wheels to situations where cushioning and shock absorption outweigh the need for extreme weight capacity.

Where Pneumatic Casters Perform Best

- Construction & Outdoor Facilities – Heavy duty pneumatic casters thrive on gravel, dirt, and asphalt.

- Logistics & Distribution Yards – Ideal for docks and loading areas where surfaces are inconsistent.

- Airport & Aerospace Settings – Sensitive equipment can be transported with reduced vibration risk.

- Event Production & Entertainment – Temporary outdoor setups benefit from mobility over grass or pavement.

In short, if the application involves rough surfaces or fragile cargo, pneumatic casters and heavy duty pneumatic tire casters deliver superior cushioning. However, users should be prepared for ongoing caster maintenance to ensure they stay inflated and ready for heavy-duty use.

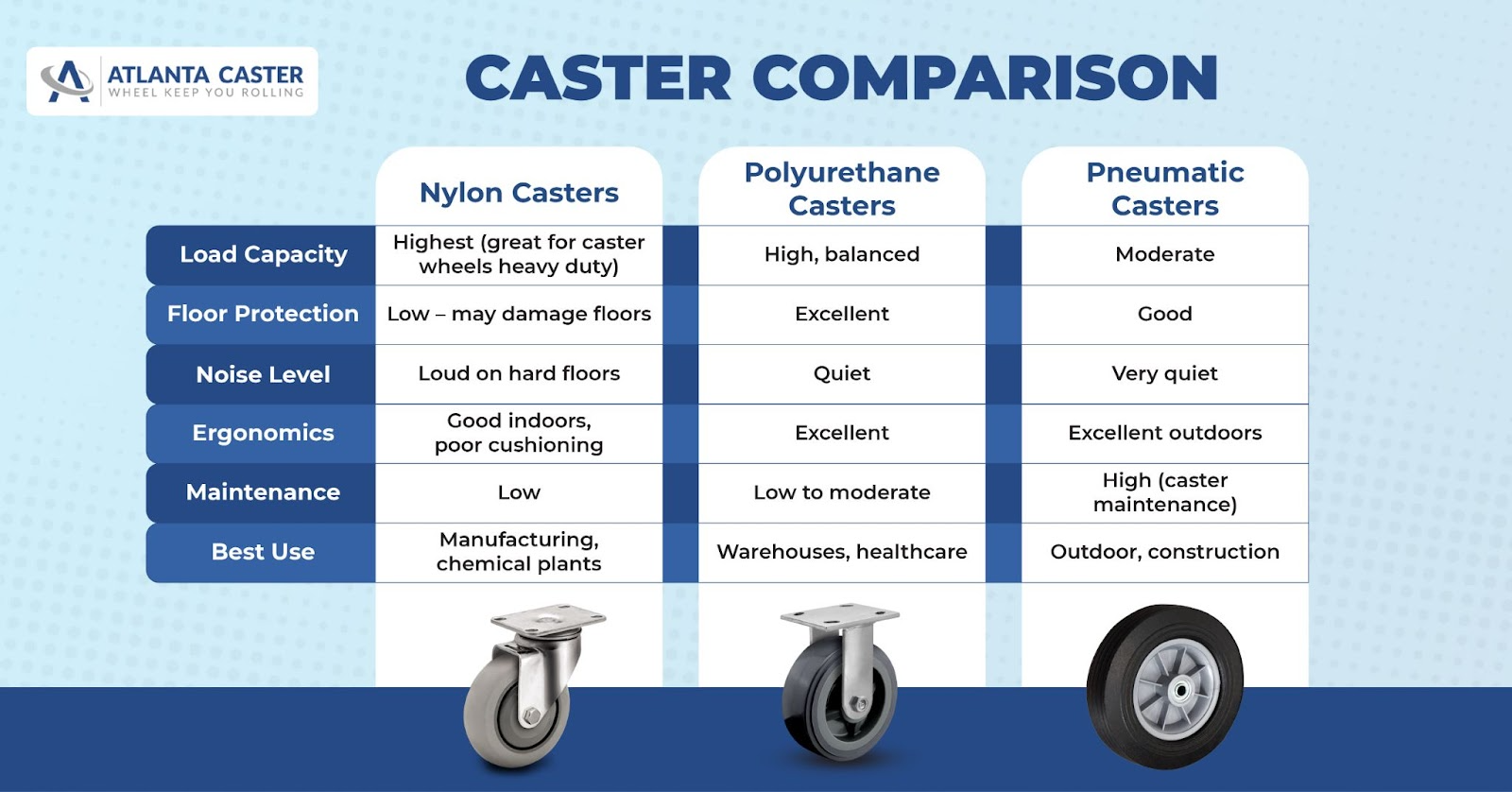

Side-by-Side Performance Comparison: Nylon vs. Polyurethane vs. Pneumatic

Choosing between nylon casters, polyurethane casters, and pneumatic casters can feel overwhelming. Each material offers clear advantages, but the right choice depends on environment, workload, and operational priorities. Below is a direct performance comparison to help facilities and engineers decide.

Load Capacity and Durability

If the job requires caster wheels heavy duty, nylon is usually the best option. Nylon casters have exceptional strength and can carry heavier loads than polyurethane or pneumatic alternatives of the same size. This makes them ideal for heavy duty industrial casters applications such as manufacturing plants or automotive facilities.

Polyurethane casters, while slightly less strong than nylon, are durable enough for most warehouses and distribution centers. They provide a balance between weight capacity and ergonomic benefits, making them one of the most versatile options for industrial casters and wheels.

Pneumatic casters fall behind in this category. Their cushioning ability comes at the expense of maximum load rating. Even heavy duty pneumatic casters or heavy duty pneumatic tire casters are better suited for moderate loads rather than extreme weights.

Floor Protection and Noise

When it comes to preserving floors and reducing workplace noise, polyurethane casters are the clear winner. They distribute weight evenly, roll quietly, and prevent scratching or gouging. This is especially valuable for warehouses with epoxy-coated floors or hospitals where noise is a concern.

Nylon casters, on the other hand, can be loud on concrete and may leave marks on softer surfaces. Their hardness is great for strength but can lead to wear and tear over time.

Pneumatic casters also perform well in this category. The air-filled design absorbs vibrations, creating one of the quietest rolling experiences. They don’t typically damage floors but require more caster maintenance to ensure consistent performance.

Maneuverability and Ergonomics

Ergonomics play a crucial role in worker safety. Reducing push and pull force can prevent injuries and improve productivity.

- Polyurethane casters excel in this area thanks to their cushioned tread and smooth rolling resistance.

- Pneumatic casters are also strong contenders, especially outdoors, because they glide over bumps and uneven terrain, reducing strain on operators.

- Nylon swivel casters are excellent in controlled indoor spaces where maneuverability around corners matters, though they don’t absorb shocks as well.

Cost, ROI, and Maintenance Needs

From a cost perspective, nylon casters often provide the best long-term ROI in harsh industrial environments. They’re inexpensive to maintain and last a long time under heavy loads.

Polyurethane casters are more expensive upfront but justify their cost through floor protection, reduced noise, and ergonomic benefits. Many facilities find the balance of durability and operator comfort worth the investment.

Pneumatic casters can be the most expensive over time due to their higher caster maintenance requirements. Air-filled wheels may need patching, refilling, or even replacement if punctured. However, in outdoor or rough-surface settings, the safety and load protection benefits outweigh these costs.

In conclusion, no single option is “best” in every scenario. Nylon casters dominate in strength and durability, polyurethane casters excel in ergonomics and floor care, while pneumatic casters win on cushioning and outdoor versatility. The final decision should align with your facility’s surfaces, loads, and operator needs.

Choosing the Right Caster for Your Industry

Selecting the right wheel isn’t just about technical specs — it’s about matching the caster to the demands of your specific industry. Below are recommendations on when to use nylon casters, polyurethane casters, or pneumatic casters depending on the setting.

Manufacturing & Heavy Equipment

Factories, assembly lines, and machining facilities often deal with oversized loads and long hours of continuous use. Here, nylon casters are a natural fit. Their high load capacity and resistance to oils and chemicals make them one of the most reliable industrial casters available. In facilities that require maneuverability, nylon swivel casters offer excellent control while still handling extreme weight.

When machinery or tooling needs caster wheels heavy duty, nylon is the safest bet. For operations with thousands of pounds of equipment on the move, heavy duty industrial casters built with nylon outperform softer materials.

Warehousing & Logistics

Warehouses demand efficiency, noise control, and floor protection. This is where polyurethane casters shine. Their cushioned tread makes moving racks, dollies, and pallet carts quieter and safer for operators. They also protect epoxy-coated or polished concrete floors from scratches.

Because they balance strength with ergonomics, casters polyurethane are widely adopted in logistics hubs, distribution centers, and fulfillment warehouses. For facilities where downtime costs money, polyurethane wheels deliver reliability without compromising worker comfort.

Construction & Outdoor Facilities

On gravel, dirt, or uneven asphalt, no wheel outperforms pneumatic casters. Their air-filled design provides shock absorption and traction, making them essential for outdoor projects. Heavy duty pneumatic casters and heavy duty pneumatic tire casters are specifically built for rugged applications where loads must travel over rough terrain without damage.

In construction sites, docks, and event production setups, these casters reduce vibration and protect fragile or sensitive equipment. Their ability to handle unpredictable surfaces makes them an invaluable part of outdoor industrial casters and wheels selections.

Healthcare & Food Processing

In clean environments, both sanitation and noise control are critical. Polyurethane casters are again the top choice because they resist cleaning agents, roll quietly, and prevent floor damage. Medical carts, lab equipment, and food service racks benefit from their balance of durability and safety.

Some facilities also incorporate stainless-steel rigs with polyurethane treads to meet strict sanitation standards. For environments where hygiene, comfort, and compliance matter, casters polyurethane are the clear leader.

Making the Right Choice

Each industry has unique demands, but the decision can be simplified:

- Nylon casters → Best for strength and chemical resistance in manufacturing.

- Polyurethane casters → Best for ergonomics, floor protection, and indoor operations.

- Pneumatic casters → Best for cushioning and traction outdoors.

By aligning caster type with environment, businesses can maximize productivity while minimizing downtime, floor repairs, and injury risks.

Extending the Life of Your Casters Through Maintenance

Even the best industrial casters and wheels require regular care to deliver long-lasting performance. Neglecting upkeep can shorten lifespan, increase operator strain, and even create safety hazards. Fortunately, consistent caster maintenance is simple and cost-effective.

Routine Inspections

Check each caster regularly for signs of wear, cracks, or flat spots. For nylon swivel casters, inspect for chips in the tread caused by impact on hard floors. For polyurethane casters, look for chunking or peeling that may occur after prolonged heavy use. Pneumatic casters should be checked for proper air pressure, as underinflated wheels can damage both the caster and the load.

Cleaning and Lubrication

Dust, debris, and chemicals can accelerate wear. Wipe down caster wheels heavy duty in manufacturing or warehouse environments to remove buildup. Adding lubrication to the swivel raceway and wheel bearings ensures smooth maneuverability, especially for heavy duty industrial casters carrying thousands of pounds.

Replacement Timing

Don’t wait for a caster to fail completely before replacing it. If wheels show deep wear, if swivels resist turning, or if pneumatic casters lose pressure repeatedly, it’s time to switch them out. Proactive replacement reduces downtime and protects equipment.

By prioritizing caster maintenance, facilities can extend the life of their equipment, protect floors, and safeguard workers. Whether you rely on nylon, polyurethane, or heavy duty pneumatic casters, regular care will keep your operation moving efficiently.

FAQs on Caster Materials and Performance

Q1. What is a caster wheel and how is it different from regular wheels?

A caster wheel is mounted inside a frame that allows it to either swivel or remain fixed. Unlike standard wheels, casters are designed to improve maneuverability and load distribution, making them essential for industrial casters and wheels.

Q2. What are caster wheels used for in industrial settings?

When people ask, “what are caster wheels used for?” the answer varies by industry. They’re commonly used on carts, racks, machinery, and dollies to simplify material handling. From warehouses to hospitals, caster wheels heavy duty help move large loads efficiently.

Q3. Do heavy duty pneumatic casters require more maintenance?

Yes. Heavy duty pneumatic casters and heavy duty pneumatic tire casters need regular air pressure checks to function properly. Without consistent caster maintenance, they may deflate or wear unevenly.

Q4. Are polyurethane casters good for high-traffic facilities?

Absolutely. Polyurethane casters are durable, reduce noise, and protect floors from damage, making them a top choice in warehouses and healthcare facilities.

Q5. When should I replace industrial casters?

If wheels show cracks, swivels resist turning, or nylon casters and polyurethane wheels flatten under load, it’s time for replacement. Timely upgrades keep operations safe and efficient.

Wrapping Up: The Best Caster Depends on Your Application

When choosing between nylon casters, polyurethane casters, and pneumatic casters, there isn’t a single “best” option. Instead, the right choice depends on your environment, load requirements, and long-term goals.

- Nylon casters excel in manufacturing and heavy-load applications. Their durability, resistance to chemicals, and high weight capacity make them the top choice for heavy duty industrial casters.

- Polyurethane casters are the most versatile, offering a balance of strength, ergonomics, and floor protection. For warehouses, logistics, and healthcare, casters polyurethane provide excellent results without sacrificing comfort.

- Pneumatic casters, especially heavy duty pneumatic tire casters, are unmatched on rough terrain. Their shock absorption protects fragile loads and makes outdoor movement safer, though they require more frequent caster maintenance.

Ultimately, your facility’s needs should guide the decision. Whether you prioritize load capacity, noise reduction, ergonomics, or surface protection, choosing the right caster will reduce downtime, protect workers, and improve overall efficiency.

Atlanta Caster offers a wide range of industrial casters and wheels designed for every setting — from smooth warehouse floors to rugged outdoor environments. Explore the full catalog today and find the perfect fit for your operation.

Email US

Email US

Hours

Hours

Visit Our Showroom

Visit Our Showroom