Pneumatic vs. Solid Caster Wheels: Which Are Better for Outdoor Use?

Apr 23rd 2025

When equipment or carts need to move across rough surfaces, uneven ground, or gravel paths, the wrong caster wheel can lead to poor performance, equipment damage, or safety risks. That’s why selecting the right outdoor casters is more important than many realize. Unlike smooth indoor floors, outdoor environments often include dirt, grass, concrete cracks, or loose surfaces—each requiring a caster designed to handle real-world conditions.

This article compares two common types of casters used in outdoor applications: pneumatic and solid wheels. We’ll examine how each performs on different terrains and which offers better durability, comfort, and load capacity. Whether you're sourcing off-road casters for industrial carts or all-terrain casters for maintenance equipment, understanding the differences can help extend the life of your gear and improve safety. Let’s look at the key features that matter most in outdoor caster selection.

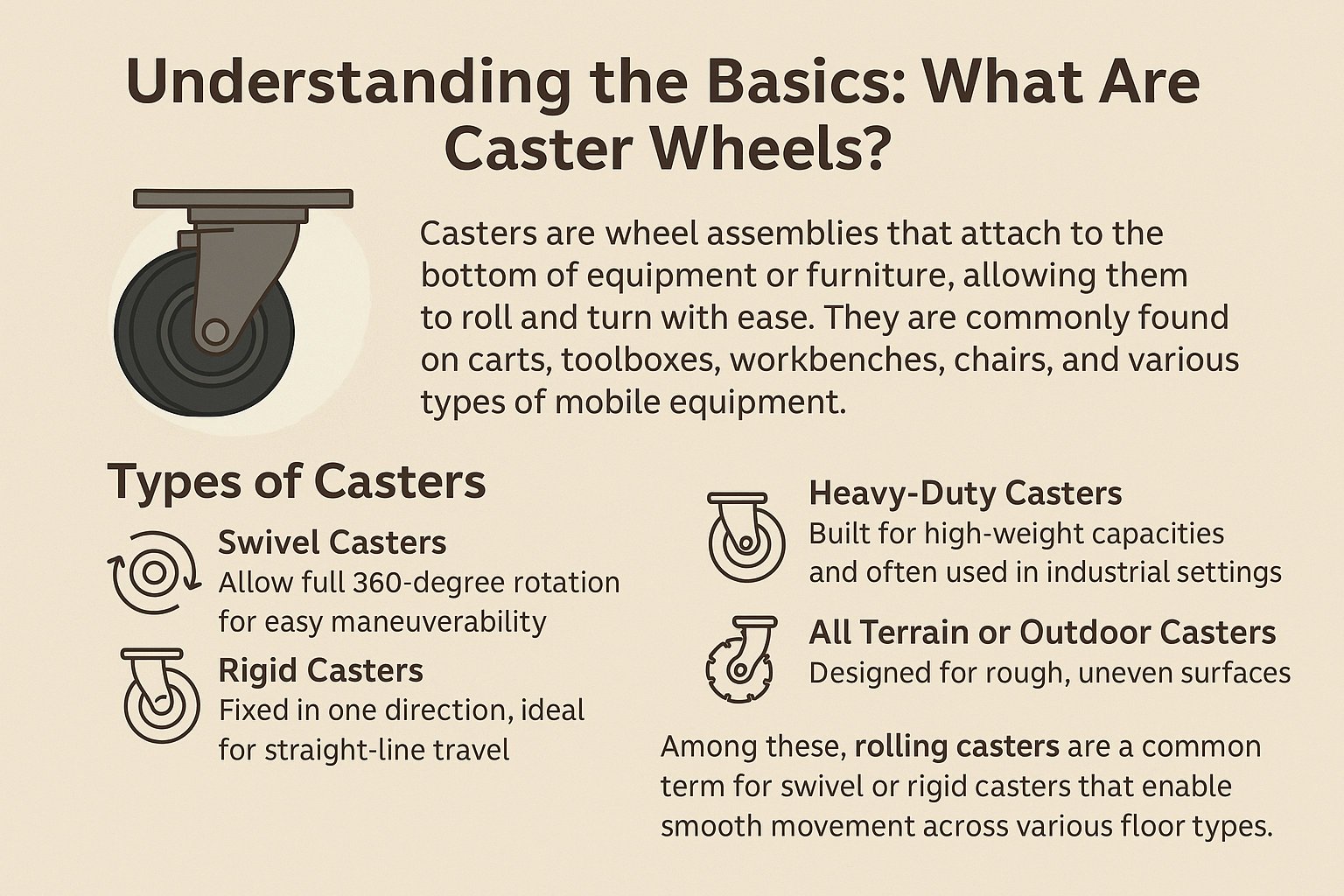

Understanding the Basics: What Are Caster Wheels?

Casters are wheel assemblies that attach to the bottom of equipment or furniture, allowing them to roll and turn with ease. They are commonly found on carts, toolboxes, workbenches, chairs, and various types of mobile equipment. The term casters refers to the complete assembly, which includes the wheel, mounting plate or stem, and a swivel or rigid frame.

Types of Casters

There are several types of casters, each designed for specific applications. These include:

- Swivel Casters: Allow full 360-degree rotation for easy maneuverability.

- Rigid Casters: Fixed in one direction, ideal for straight-line travel.

- Locking Casters: Include a braking mechanism to prevent rolling or swiveling.

- Heavy-Duty Casters: Built for high-weight capacities and often used in industrial settings.

- All Terrain or Outdoor Casters: Designed for rough, uneven surfaces.

Among these, rolling casters are a common term for swivel or rigid casters that enable smooth movement across various floor types.

Replacement Casters

Over time, caster wheels can wear out or become damaged. Replacement casters restore mobility without replacing the entire equipment. They are available in various sizes and materials to match original specifications and are commonly used in warehouses, manufacturing, offices, and medical environments.

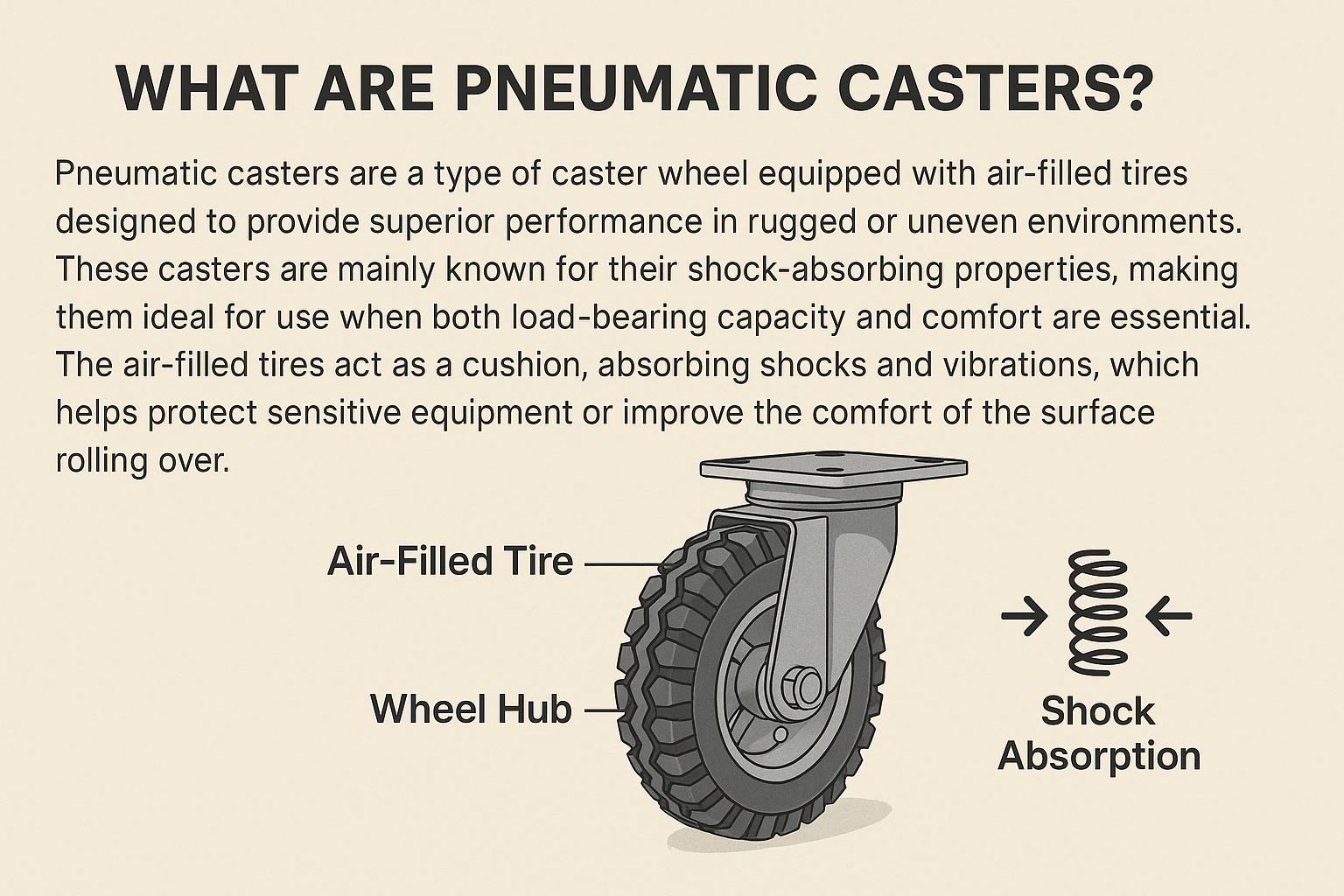

What Are Pneumatic Casters?

Pneumatic casters are a type of caster wheel equipped with air-filled tires designed to provide superior performance in rugged or uneven environments. These casters are mainly known for their shock-absorbing properties, making them ideal for use when both load-bearing capacity and comfort are essential. The air-filled tires act as a cushion, absorbing shocks and vibrations, which helps protect sensitive equipment or improve the comfort of the surface rolling over.

Construction of Pneumatic Casters

- Air-Filled Tires: Pneumatic casters have tires that are filled with air, similar to those found on vehicles. These tires offer flexibility and cushioning, which helps absorb shocks from uneven or rough surfaces.

- Tread: The tire's tread pattern is designed for traction and stability. Pneumatic casters typically have a rugged, deep-tread design that improves grip on various surfaces, such as gravel, dirt, or grass.

- Wheel Hub: The wheel hub is the core component that attaches the tire to the caster. It is typically made of durable materials like steel, ensuring strength and long-lasting performance.

Strengths of Pneumatic Casters

- Shock Absorption: The air-filled tires provide a natural cushion against bumps and impacts, reducing the amount of shock transferred to the equipment or surfaces.

- Noise Reduction: The cushioning effect also helps reduce noise, making pneumatic casters suitable for environments where noise levels must be minimized.

- Ride Quality: The tires provide a smoother ride than solid or rigid rubber casters, making them particularly beneficial when moving over rough or uneven terrain.

Best Applications of Pneumatic Casters

- Off-Road Casters: Pneumatic casters excel in off-road applications where surfaces may be irregular, such as construction sites, farms, or outdoor events.

- All-Terrain Casters: These casters, with their shock-absorbing features, are perfect for navigating challenging all-terrain surfaces like gravel, grass, or sand.

- Rugged Work Environments: Pneumatic casters are ideal for environments with heavy-duty equipment and tools, like warehouses, factories, and loading docks, where smooth movement across harsh surfaces is necessary.

What Are Solid Wheels?

Solid wheels are caster wheels made from a single, solid material, such as rubber, plastic, or polyurethane. Unlike pneumatic casters that are inflated with air, solid wheels have no air-filled tire and are designed to provide a more durable and maintenance-free solution. These wheels are known for their robustness and ability to perform well on smooth or indoor surfaces. Solid wheels can handle various loads and are often used in environments where the potential for punctures or damage from rough terrain is a concern.

How Solid Wheels Differ from Pneumatic Casters

- Construction: Pneumatic casters feature air-filled tires that cushion impacts, while solid wheels are made from a single, solid material with no air inside.

- Shock Absorption: Pneumatic casters excel at absorbing shocks and vibrations due to their air-filled tires, making them ideal for rough and uneven surfaces. On the other hand, solid wheels do not offer ample shock absorption, which can lead to a bumpier ride on uneven terrain.

- Durability: Solid wheels are more durable and resistant to punctures than pneumatic casters, which can be prone to flat tires if they encounter sharp objects or rough surfaces.

Foam-Filled Wheels as a Hybrid

Foam-filled wheels combine the benefits of both solid and pneumatic wheels. These wheels are filled with foam instead of air, providing a cushioning effect similar to pneumatic casters but without the risk of punctures. Foam-filled wheels are lightweight, offer a smoother ride than solid wheels, and are typically more wear and tear-resistant than traditional air-filled tires. They serve as a hybrid option for those who want a balance between the shock-absorbing properties of pneumatic casters and the durability and maintenance-free nature of solid wheels.

Strengths of Solid and Foam-Filled Wheels

- Durability: Solid wheels are highly durable and can withstand heavy use without the risk of punctures or air loss. Foam-filled wheels are more durable than pneumatic casters since they do not require air.

- Resistance to Punctures: Solid and foam-filled wheels are more resistant to punctures than pneumatic casters. Since there is no air in these wheels, there's no risk of them going flat, making them a more reliable option in environments with sharp objects or rough surfaces.

- Less Maintenance: Solid and foam-filled wheels require less maintenance than pneumatic casters. They don't need to be inflated, and foam-filled wheels are generally more low-maintenance than pneumatic options since they do not require constant checking for air pressure.

Best Applications for Solid and Foam-Filled Wheels

- Outdoor Casters: Both solid and foam-filled wheels are great for outdoor applications where puncture resistance is a priority, such as on equipment carts, lawnmowers, and utility trailers.

- Replacement Casters: Solid and foam-filled wheels are often chosen as they are durable and easy to maintain when replacing worn-out wheels.

Side-by-Side Comparison: Pneumatic vs. Solid Wheels

The following table gives a detailed comparison between pneumatic and solid wheels:

|

Feature |

Pneumatic Wheels |

Solid Wheels |

|

Load Capacity |

Typically, it has a lower load capacity than solid wheels due to the air-filled tire structure. |

They have a higher load capacity and are made of rubber or polyurethane. |

|

Terrain Adaptability |

Excellent for rough, uneven, or off-road terrain. Ideal for off-road casters and outdoor casters. |

Best for smooth, flat surfaces. Less effective on rugged terrain. |

|

Noise Levels |

Lower noise levels due to shock absorption of the air-filled tires. |

Higher noise levels, mainly when used on hard or uneven surfaces. |

|

Maintenance Needs |

Higher maintenance due to the need for air pressure monitoring and the potential risk of punctures. |

Minimal maintenance—no need to check air pressure, and they resist punctures. |

|

Cost |

Generally have a higher price range due to the complex design and air-filled nature. |

They are more affordable, simpler, and made from solid materials. |

|

Longevity |

It can wear and tear over time, especially from punctures. |

Longer-lasting, as they are resistant to puncture damage and are built to handle more rugged conditions. |

|

Practical Advice |

These are best for environments where shock absorption, smooth ride quality, and off-road performance are important, such as construction sites or uneven outdoor terrain. Choose pneumatic casters for all-terrain casters. |

They are best for smooth indoor surfaces or areas where punctures could be an issue. |

When is the Right Time to Choose Each Option Based on Job Type?

- Pneumatic Wheels: Choose pneumatic wheels when your work environment involves rough or uneven terrain, such as gravel, grass, dirt, or outdoor use. These are ideal for off-road casters, outdoor casters, and heavy-duty applications that require a smoother, shock-absorbing ride.

- Solid Wheels: Solid wheels are a great choice if you work on smooth surfaces or need casters that are easy to maintain. They are very useful in indoor settings or for equipment that needs to be moved on hard floors without worrying about punctures. Consider solid casters as replacement casters in environments like warehouses, factories, or rolling carts that will not be exposed to rough terrain.

Environmental Impact: Terrain Types and Caster Performance

The performance of caster wheels largely depends on the type of terrain they encounter. Whether navigating gravel, dirt, asphalt, concrete, grass, or uneven ground, choosing the right caster can significantly impact the efficiency, comfort, and longevity of both the wheels and the equipment. In this section, we’ll compare the performance of pneumatic casters and solid wheels across various surfaces and introduce all-terrain casters as an ideal solution for mixed or challenging environments.

Performance on Gravel and Dirt

Regarding gravel, pneumatic casters excel due to their air-filled tires, which provide cushioning and help absorb the impacts of uneven, loose surfaces. These are an excellent choice as outdoor casters and off-road casters that need to perform well in such environments. In contrast, solid wheels often struggle on gravel, causing resistance and a bumpier ride. The airless nature of solid wheels makes them less effective on loose materials like gravel.

Similarly, pneumatic casters perform well on dirt surfaces. The shock-absorbing capacity of the air-filled tires helps smooth out the ride, allowing the casters to glide over uneven ground with minimal effort. Solid wheels, however, are less effective on dirt due to their rigid nature, leading to poor traction and a rougher ride. All-terrain casters are an ideal solution for gravel and dirt, combining the durability and resistance of solid wheels with the shock absorption of pneumatic casters, making them perfect for these mixed, rugged environments.

Performance on Asphalt and Concrete

Both pneumatic casters and solid wheels perform well on asphalt and concrete but for different reasons. Pneumatic casters provide a comfortable ride due to their ability to absorb shock. At the same time, solid wheels perform just as effectively on these smooth, hard surfaces as they roll effortlessly without any air pressure concerns. However, when considering all-terrain casters, their versatile design allows them to offer consistent performance on smooth surfaces like asphalt and on occasional uneven patches that might be found outdoors. For this reason, all-terrain casters are a practical solution when the surface can vary.

Performance on Grass and Uneven Terrain

For grass, pneumatic casters are the best option as they can adapt to uneven, soft surfaces while minimizing impact. The air-filled tires allow the caster to roll smoothly without sinking or becoming stuck. On the other hand, solid wheels tend to struggle on grass, often causing the equipment to sink or experience difficulty moving across the surface. Once again, all-terrain casters are the optimal choice here, as they offer the right balance of durability and cushioning to handle grass and other mixed surfaces like dirt or gravel, making them a versatile option for outdoor environments.

When navigating uneven terrain, pneumatic casters provide excellent shock absorption, which is ideal for rugged and bumpy surfaces. Solid wheels are not well-suited for this type of terrain, as they do not offer the same level of comfort and tend to cause jarring movements. This is where all-terrain casters genuinely shine, as their design incorporates features allowing them to traverse mixed and uneven surfaces smoothly, ensuring comfort and efficiency.

All-Terrain Casters: The Solution for Mixed Surfaces

For environments with varying surfaces, all-terrain casters are the perfect solution. These casters combine the benefits of pneumatic casters and solid wheels—the shock-absorbing qualities make them durable and puncture-resistant of solid wheels. All-terrain casters are built to handle a wide range of surfaces, including gravel, dirt, grass, and even uneven terrain, making them an excellent choice for industries that require mobility across diverse ground conditions.

Exploring Different Types of Casters for Outdoor Use

Choosing the right wheel material is crucial when selecting casters for outdoor use. Rubber wheels are quiet and forgiving, ideal for absorbing shock and reducing noise. Polyurethane caster wheels offer excellent performance on smooth surfaces, providing durability and a smooth ride. Phenolic caster wheels are heavy-duty and heat-resistant, perfect for harsh outdoor conditions and heavy loads. Nylon wheels are lightweight yet rugged, suitable for outdoor environments that require mobility without compromising strength. Additionally, hybrid or specialty casters, such as phenolic wheels with a rubber coating or all-terrain options, offer versatility for mixed surfaces and demanding tasks.

Maintenance Tips for Outdoor Casters

Proper maintenance of outdoor casters ensures longevity and performance. Regularly cleaning casters to remove debris and dirt helps prevent corrosion and keeps them rolling smoothly. For pneumatic casters, check inflation levels to maintain optimal performance and inspect tread wear to avoid slippage. Also, ensure the axle's health by checking for any signs of rust or wear. If a caster becomes damaged or worn beyond repair, it's time to consider replacement casters. For environments requiring minimal upkeep, solid wheels offer a great alternative to pneumatic casters. Rolling casters should be checked periodically to ensure they continue to meet your needs.

Cost vs. Longevity: Making the Right Investment

When evaluating outdoor casters, consider both upfront costs and lifetime performance. While solid wheels or pneumatic casters may have lower initial costs, investing in premium all-terrain casters can provide better longevity and performance in the long run, especially in rugged conditions. Choosing the wrong wheel type can lead to costly downtime due to breakdowns, maintenance, or inefficient movement. Though pricier initially, premium casters can reduce these risks, offering smoother performance and excellent durability. For high-demand environments, it often makes sense to invest in all-terrain casters to ensure minimal disruption and maximize return on investment.

Use Case Scenarios: What Works Best Where

The following are different scenarios where different types of casters are used:

Construction Sites

Pneumatic casters are ideal for construction sites with standard uneven, rough surfaces. Their shock-absorbing air-filled tires help navigate gravel, dirt, and other challenging terrains. For example, construction equipment carts using off-road casters with pneumatic wheels handle heavy loads smoothly, preventing damage to tools and ensuring efficient movement.

Warehousing

Solid or polyurethane caster wheels are commonly used in warehousing for their durability on smooth, hard floors. These casters are low-maintenance and can support heavy loads. For example, pallet jacks and shelving units often use solid wheels to ensure easy maneuverability in tight aisles and minimize maintenance downtime.

Foodservice Carts Outdoors

Rubber wheels are perfect for food service carts outdoors. They offer a smooth, quiet ride and cushion against rough surfaces. These casters also resist corrosion from exposure to moisture. For example, food trucks or catering carts use rubber wheels to ensure stability and ease of movement, even in outdoor or uneven environments.

Industrial Applications

Depending on the surface, phenolic casters or nylon wheels are suitable for industrial applications. Phenolic caster wheels are durable and heat-resistant, ideal for factories with heavy machinery. On the other hand, nylon wheels are lightweight yet rugged, making them perfect for moving heavy equipment across smooth indoor floors while handling heavy-duty tasks.

Wrapping up

Pneumatic casters provide excellent shock absorption and are ideal for uneven terrains like gravel and dirt, while solid wheels are durable, low-maintenance, and perform well on smooth surfaces. Each caster type offers distinct advantages, depending on your needs. When choosing casters, assessing your specific terrain and load requirements is crucial to make sure of optimal performance. For outdoor applications, all-terrain casters may offer the versatility you need. If you're uncertain which option is best, contact Atlanta Caster for expert advice on selecting the right outdoor or replacement casters to meet your needs.

Email US

Email US

Hours

Hours

Visit Our Showroom

Visit Our Showroom