Step-by-Step Guide: How to Measure Casters for a Perfect Fit

Apr 28th 2025

Selecting the right casters is essential for smooth movement and stability, whether replacing chair wheels or outfitting industrial equipment. Proper measurements help ensure compatibility, prevent uneven wear, and improve overall performance.

If you’re unsure where to start, this guide will walk you through the process, including how to measure a swivel plate, wheel diameter, and overall height. Accurate measurements are key to selecting casters that fit securely and function appropriately for your application.

Whether you're working with furniture, medical carts, or heavy-duty machinery, knowing how to measure a swivel plate and other key dimensions will help you find the right replacement. By the end of this guide, you'll have the knowledge and confidence to select casters that keep your equipment rolling efficiently.

Let’s get started on measuring casters the right way.

Why Accurate Caster Measurements Matter

Casters may be small components, but they significantly impact your equipment’s performance. The proper caster wheels ensure smooth movement, reduce strain on flooring, and uplift overall safety by preventing instability or tipping. High-quality casters also extend the lifespan of your equipment by minimizing wear and tear. Whether for office chairs, medical carts, or heavy-duty machinery, choosing the right casters improves mobility, efficiency, and durability in any application. The wrong size can lead to:

- Uneven rolling or wobbling.

- Difficulty steering or maneuvering, especially with swivel plates.

- Premature wear on the caster or the equipment.

- Damage to your flooring or work environment.

Whether replacing rolling chair casters or upgrading durable, superior casters for industrial equipment, precise measurements are crucial to avoid costly mistakes.

Tools You’ll Need for Measuring Casters

Before we get into the specifics, make sure you have the right tools on hand to take accurate caster measurements:

- Measuring Tape: Essential for measuring diameter, mounting plates, and height.

- Angle Finder: This tool will come in handy if you need to measure caster angles.

- Caliper or Ruler: For small swivel and caster inserts, you’ll need more precision.

- Notebook or App: Jot down your measurements to reference later.

Step 1: Understanding the Key Components of a Caster

Before jumping into how to measure caster wheels, it’s essential to identify the main parts of a caster. These include:

- Wheel: The circular part that touches the ground.

- Swivel Plate: Allows the caster to rotate and steer in multiple directions.

- Mounting Plate or Stem: The attachment point that connects the caster to your equipment.

- Bracket or Housing: Holds everything together, sometimes with a ball-bearing swivel plate for smoother rotation.

Knowing about these parts helps with measuring everything accurately.

Step 2: How to Measure a Caster Wheel

The wheel is the most critical part of any caster because it directly affects mobility, load capacity, and durability. It determines how smoothly equipment moves, how much weight the caster can support, and how well it performs on different surfaces. The wheel material also plays a key role in noise reduction, floor protection, and resistance to wear. Choosing the right wheel ensures efficient, safe, and long-lasting performance. Here’s how to measure it:

- Measure the Wheel Diameter: Use your tape measure to find the distance across the center of the wheel. This measurement determines the size of the caster wheel. For example, smaller equipment like stools may need small swivel casters, while heavy-duty machinery may require larger wheels.

Pro Tip: Check a caster wheel size chart for industry-standard sizes. - Determine the Tread Width: This is the width of the wheel surface that touches the ground. Wider treads distribute weight more evenly, making them ideal for heavy loads or soft flooring.

- Check the Wheel Material: Depending on your application, choose the right material. For example:

- Rubber for quiet movement on hospital floors.

- Polyurethane for durability in industrial settings.

- Steel or iron for heavy machinery.

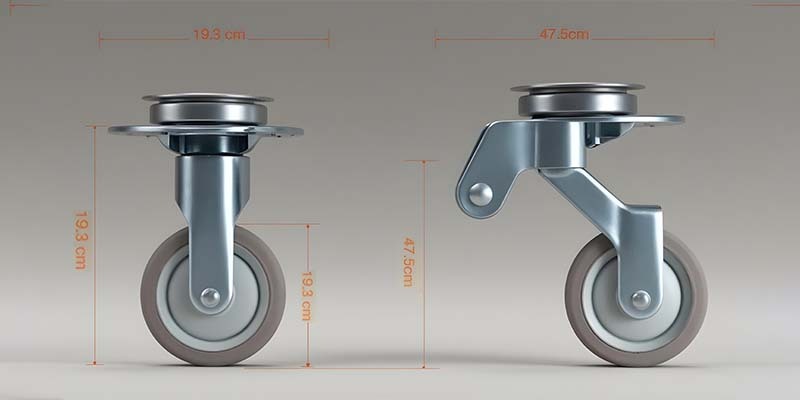

Step 3: How to Measure a Swivel Plate

The swivel plate connects the caster to your equipment and is essential for smooth, controlled movement. It allows the caster to rotate 360 degrees, making maneuvering carts, chairs, and machinery easier. A well-designed swivel plate ensures stability and reduces strain on the equipment. Knowing how to measure a swivel plate is essential when replacing casters, as the right size helps with accurate fit and maximize performance for your specific application. Here’s how to measure it:

- Measure the Plate Dimensions: Use your measuring tape to determine the length and width of the plate. Ensure it matches the mounting space on your equipment.

- Note the Bolt Hole Pattern: Many swivel plates have pre-drilled bolt holes. Measure the distance between them (center-to-center) to ensure compatibility.

- Inspect the Swivel Mechanism: Check the ball-bearing swivel plate to ensure it rotates smoothly if you're replacing worn-out parts.

Step 4: How to Measure the Mounting Height

The mounting height is the total distance from the bottom of the wheel to the top of the mounting plate or stem. Follow these steps:

- Place the caster on a flat surface.

- Measure vertically from the floor to the top of the mounting plate or stem.

This measurement is especially important if you’re replacing chair replacement wheels or wheels for a table to ensure the height matches your original setup.

Step 5: How to Measure Caster Inserts or Stems

Caster inserts or stems are the connecting components that attach casters to equipment, ensuring a secure and stable fit. They come in various types, including threaded, grip ring, and grip neck stems, each designed for specific applications. Choosing the correct insert size is essential for safety, proper weight distribution, and smooth mobility in furniture, carts, and industrial equipment.

For stem-mounted casters (common on chairs, stools, and some carts), you’ll need to measure the stem or caster inserts:

- Measure the Diameter: Use a caliper or ruler to accurately measure the thickness of the caster stem. Place the tool around the widest part of the stem to get an exact measurement. A proper diameter ensures a secure fit, preventing wobbling or instability when the caster is installed on furniture, carts, or equipment.

- Check the Length: Measure the stem from its base to tip with a ruler or caliper. Accurate length measurement is crucial, as a stem that is too short may not provide enough support, while one that is too long may not fit properly. Ensuring the correct length helps maintain stability and smooth mobility.

- Verify Stem Type: There are different stem types, including threaded, grip ring, and grip neck stems. Identifying the correct type ensures compatibility with your equipment. Matching the stem type and size prevents installation issues and improves caster performance, ensuring safe and efficient movement for chairs, carts, and industrial applications.

Step 6: Measuring Caster Angles

In specialized applications, measuring caster angles ensures precise steering and optimal maneuverability. This is especially important for medical equipment, automotive applications, and heavy-duty machinery, where alignment affects performance. Proper caster angle measurements help maintain stability, reduce tire wear, and improve control, ensuring smooth and efficient movement in demanding environments.

- Use an angle finder which helps to determine the angle of the caster.

- Align the tool with the caster's mounting point and wheel to find the angle.

Pro Tip: Many manufacturers offer guides or support if you’re unsure how to measure the caster with an angle finder.

Step 7: Testing and Compatibility

Once you’ve taken your measurements, the next step is testing for compatibility to ensure a proper fit. Compare your measurements with the manufacturer’s specifications to confirm that the caster will securely attach to your equipment. Check the stem or mounting plate size, wheel diameter, and weight capacity. Testing compatibility helps prevent installation issues, ensures smooth movement, and improves stability. A well-fitted caster improves safety, extends equipment life, and optimizes overall performance. Perform a simple caster test:

- Check the Fit: Attach the caster to your equipment to ensure the mounting plate or stem fits securely.

- Roll and Swivel: Move the equipment to test for smooth rolling and swiveling.

- Inspect Load Capacity: Confirm that the caster can handle the weight of the equipment and its contents.

If everything checks out, you’re ready to roll—literally!

FAQs

1. How is the caster measured?

Casters are measured by determining the wheel diameter, tread width, mounting height, and swivel plate dimensions. You’ll also need to measure the stem diameter and length for stem-mounted casters.

2. How do I choose the most minor casters for stools or chairs?

Look for casters with smaller wheel diameters (e.g., 2-3 inches) and lightweight designs. Use a caster wheel size chart to confirm dimensions.

3. How do you measure caster thread size?

Measure the stem diameter with a caliper (e.g., 3/8"), then check the thread pitch using a gauge or bolt. Identify if threads are coarse (UNC) or OK (UNF). For metric threads, measure the distance between threads in millimeters.

4. How to determine caster wheel size?

Measure the wheel diameter across the center and the tread width. Refer to a caster wheel size chart for standard sizes. Smaller wheels suit lighter applications, while larger wheels handle heavier loads.

5. How do you measure caster?

Measure the wheel diameter, mounting plate or stem dimensions, mounting height, and swivel radius. Ensure all measurements align with your equipment’s proper fit and operation requirements.

6. How to measure chair wheel size?

Measure the wheel diameter (2-3"), stem diameter (7/16"), and stem length (1-1.5"). Choose materials based on your flooring, like polyurethane for hardwood or nylon for carpet.

7. What size casters should I use?

Choose based on load capacity and flooring. Larger wheels (6-8") handle heavy loads, while smaller ones (2-3") suit light-duty tasks. Match the materials to the floor type and check the mounting height.

Final Thoughts: The Perfect Fit for Your Equipment

Measuring casters doesn’t have to be intimidating. By following these steps, you’ll ensure that your casters fit perfectly, whether you’re outfitting hospital beds, warehouse carts, or office chairs. Remember, the key is precision—take your time, double-check your measurements, and always test compatibility before committing.

Ready to Upgrade Your Casters?

I'm here to assist if you need help finding the right casters for your equipment. Contact Atlanta Caster today for expert guidance and a wide selection of durable superior casters tailored to your needs. Let’s make your equipment roll better, last longer, and perform flawlessly.

Email US

Email US

Hours

Hours

Visit Our Showroom

Visit Our Showroom