Tackling Challenges in the Caster and Wheel Industry

Feb 5th 2025

Choosing the correct casters and wheels is critical for operational efficiency and safety across industries. Businesses rely on wheels for carts and chairs to streamline daily tasks, yet common challenges—such as durability, maneuverability, and load management—can compromise performance. When unsuitable casters or wheels are selected, equipment inefficiency, workplace safety risks, and escalating maintenance costs often follow.

For instance, wheels for carts that cannot handle heavy loads may result in breakdowns or delays. At the same time, chairs with casters that lack proper mobility can hinder productivity in office environments. These challenges not only disrupt workflows but also increase expenses over time.

In this discussion, we’ll learn about the most pressing issues faced in the caster and wheel industry and practical solutions to address them effectively. By understanding these factors, businesses can make informed decisions and avoid costly setbacks.

The Longevity Problem: Why Wheels Fail Prematurely

Premature wheel failure is a persistent issue caused by mismatched materials, improper sizing, and exceeding weight capacities. To ensure long-lasting performance, it’s crucial to align caster and wheel selection with the specific demands of the environment and application. Below, we’ll get into two significant causes of wheel failure: material mismatch and overloading.

Material Mismatch

Using the wrong wheel material for the environment is a common cause of premature failure. For example, pneumatic wheels, designed for shock absorption and smooth operation, deteriorate quickly in wet or chemically corrosive environments. Similarly, stem casters often fail in applications with heavy, continuous loads exceeding design limitations.

In industrial settings, wheels for carts made of soft rubber may wear out rapidly on abrasive surfaces, while more complex materials like polyurethane may crack under exposure to extreme cold. These issues emphasize the importance of selecting materials tailored to the environment. Compatibility with floor type, temperature, and chemical exposure can significantly extend wheel life, improving performance and cost efficiency.

Overloading and Its Consequences

Overloading is another frequent cause of wheel failure, mainly when undersized options like 3 inch caster wheels are used in high-load environments. These smaller wheels are not designed to withstand substantial weight, leading to deformation, difficulty maneuvering, and even total failure.

A typical scenario involves replacement casters installed on equipment without proper attention to weight limits. For instance, swapping out damaged heavy duty casters with lighter-duty options often results in faster breakdowns and unsafe operating conditions. To avoid these problems, selecting casters with an appropriate load rating and size for the application is essential.

Maneuverability Challenges: The Struggle with Mobility

Ensuring smooth mobility is essential for productivity, yet maneuverability challenges can hinder operations in tight spaces and high-demand settings. From navigating compact environments to addressing design flaws in wheel configurations, mobility issues often arise due to improper caster or wheel choices. Below, we examine two key aspects: the challenges of navigating tight spaces and the drawbacks of dual front wheels for carts.

Navigating Tight Spaces

Standard wheels frequently fail in environments with limited space, making precision and stability difficult to achieve. In such cases, low-profile heavy duty casters with leveling feet offer a superior alternative, combining compact design with robust load-bearing capacity and adjustable stability.

-

Stability- Leveling feet help compensate for uneven floors, ensuring a steady platform.

-

Smooth Turns- Low-profile designs enable effortless navigation around tight corners without compromising durability.

However, poorly designed systems—such as dual front swivel setups—can lead to erratic movement and imprecise steering. These configurations often lack the engineering required for synchronized turning, creating friction and instability during use. Selecting casters designed for compact environments ensures efficiency and safety.

The Issue with Dual Front Wheels for Carts

Dual front wheels on carts are intended to improve load distribution, yet they often suffer from misalignment and instability, particularly in high-speed or heavy duty applications.

Common Issues:

-

Design flaws cause uneven wear on wheels.

-

Poor weight distribution leads to wobbling or tipping.

heavy duty swivel mechanisms are essential to counteract these issues. However, substandard designs or improper assembly can exacerbate instability, particularly when moving at higher speeds or handling sharp turns.

To avoid such problems, it is essential to invest in well-designed dual front wheel systems that feature precision alignment and robust construction. Proper maintenance, including routine checks for wear and alignment, can further mitigate these challenges, ensuring long-term performance and mobility.

Sizing Dilemmas: When Wheel Dimensions Create Problems

Wheel size determines performance, stability, and ease of movement. Improper sizing, whether too large or too small, can create various issues in industrial and everyday applications. Below, we’ll examine two key challenges: balancing wheel diameter with application requirements and resolving fitting issues in furniture and equipment.

Balancing Diameter with Application

Choosing the correct wheel diameter is essential to balancing precision, stability, and practicality. Oversized wheels, such as 7'' diameter wide wheels pneumatic wheels, are excellent for covering uneven terrain or handling heavy loads but often come with drawbacks:

-

Reduced Precision- Larger wheels can make sharp turns and fine adjustments difficult.

-

Space Limitations- They require more room, which can be challenging in compact environments.

On the other hand, smaller options like big caster wheels are better suited for tight spaces but struggle on uneven or rough surfaces. Their reduced diameter can lead to issues such as:

-

Increased Wear- Constant exposure to bumps and debris accelerates deterioration.

-

Reduced Load Capacity- Smaller wheels may need to support heavy equipment more effectively.

Striking the right balance between size and application ensures optimal performance while minimizing wear and tear. It is a best practice to consult load ratings and workspace dimensions before selecting a wheel diameter.

Fitting Issues with Furniture and Equipment

,

,

Another common sizing dilemma is finding the correct cabinet design or equipment wheelbase. Cabinets that store heavy items require wheels capable of supporting weight without compromising aesthetics or functionality.

Key Challenges:

-

Wheels that are too large can detract from the furniture’s design.

-

Smaller wheels may fail to support the load, leading to poor maneuverability.

Incorrect wheel sizing can also create issues in tight workspaces, where overly large bases restrict movement or cause obstructions. Properly sized wheels allow for smooth navigation without sacrificing stability or aesthetics.

To avoid these problems, manufacturers should prioritize wheels designed specifically for furniture and equipment applications. Custom options that blend durability with design appeal are ideal for ensuring both form and function.

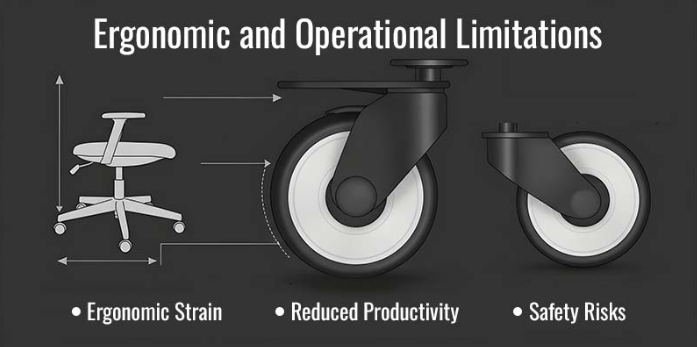

Ergonomic and Operational Limitations

Casters and wheels are pivotal in maintaining comfort and efficiency across various environments, from offices to industrial settings. However, well-designed or matched solutions can lead to ergonomic strain, reduced productivity, and even safety risks. This section highlights the impact of casters for chairs on users' well-being and the operational challenges associated with heavy duty wheels in industrial applications.

Strains from Chairs with Casters

Casters for chairs are essential for mobility and convenience, yet poorly designed options can negatively impact users' comfort and health. Chairs with casters that roll unevenly or resist movement can force users into awkward sitting positions, leading to posture-related issues such as back and neck strain. Additionally, low-quality casters often generate noise disturbances, creating an unproductive environment in offices and schools. The problem is further compounded when incompatible replacement casters are used. For instance, mismatched sizes or materials can cause instability, floor damage, or poor maneuverability, exacerbating ergonomic and operational challenges. Selecting high-quality, ergonomic casters that ensure smooth, noise-free movement can significantly uplift user comfort and productivity, reducing workplace disruptions and long-term physical strain.

Handling Heavy Loads in Industrial Settings

heavy duty cartwheels are critical for industrial operations, but they often need to improve due to material limitations or flawed designs. Wheels marketed for high-weight capacities may degrade quickly under real-world conditions, mainly if constructed from subpar materials or lacking proper load distribution mechanisms. This can result in warping, buckling, or complete failure, particularly in dynamic environments with frequent movement. Upgrading to heavy duty swivel casters with reinforced frames and durable materials like polyurethane provides better load management and improved maneuverability. Routine maintenance, including wear and alignment issues inspections, further ensures long-term reliability. By investing in robust, high-performance components, businesses can minimize downtime and maintain operational efficiency while safely managing heavy loads.

Addressing Industry-Wide Design Flaws

While the caster and wheel industry continues to evolve, design flaws in critical components often hinder safety, efficiency, and performance. Two areas where these shortcomings are most apparent are the overlooked stability features in leveling casters and the underperformance of dual front wheels and smaller caster models. These gaps highlight the need for improved engineering and awareness about the long-term benefits of innovation.

The Overlooked Importance of Leveling Casters

Stability is a fundamental requirement for casters in industrial and commercial settings, yet many manufacturers must address it adequately in their designs. Leveling casters, exceptionally low-profile heavy duty casters with leveling feet, are engineered to provide stability on uneven surfaces. However, design compromises, such as inadequate weight distribution or poor adjustability, often limit their effectiveness.

Despite their potential to uplift safety and operational efficiency, some industries hesitate to invest in these solutions, prioritizing short-term cost savings over long-term benefits. This reluctance can lead to frequent equipment failures and increased maintenance costs. Industries that adopt leveling casters tailored to their specific needs can improve stability, reduce workplace risks, and ensure smoother operations, making them a worthwhile investment.

Innovations Needed for Dual Wheels and Castor Small

Dual front wheels for carts and castor small models are critical for applications requiring precision and flexibility, yet their performance often needs to improve. Misaligned dual front wheels can cause instability, uneven wear, and inefficiencies in high-demand environments such as logistics and manufacturing. Similarly, smaller caster models frequently need help with durability and load management, limiting their usability in demanding applications.

These limitations have driven demand for innovative designs that offer better alignment, better weight distribution, and improved durability. For example, industries relying on carts for heavy loads often report difficulty navigating tight spaces or maintaining stability at high speeds due to flaws in current models. Addressing these issues requires manufacturers to prioritize high-performance materials and advanced engineering techniques.The industry can deliver solutions that align with user expectations and operational requirements by meeting these needs.

Wrapping up

The caster and wheel industry must continue prioritizing durability, ergonomic design, and adaptability to meet the diverse needs of its users. From ensuring stability in wheels for carts to improving the reliability of heavy duty cartwheels and selecting appropriate replacement casters, addressing these pain points is essential for uplifting safety, efficiency, and productivity. Businesses that invest in well-engineered solutions reduce downtime and maintenance costs and create safer and more effective work environments.

To get the best recommendations from experts and a wide range of high-quality caster and wheel solutions, trust Atlanta Caster to keep your operations moving forward.

Email US

Email US

Hours

Hours

Visit Our Showroom

Visit Our Showroom