The Science Behind Choosing the Right Caster for Different Surfaces

May 26th 2025

Casters are vital components used in a wide range of industries to ensure mobility and ease of transportation for equipment, machinery, and furniture. From healthcare to manufacturing, casters play a significant role in enhancing efficiency and reducing physical strain. However, selecting the right caster for a particular surface requires an understanding of several factors such as the type of surface, load capacity, caster types, bearing types, and caster maintenance. This article will explore the science behind choosing the right caster for different surfaces and how each factor impacts performance. We will cover topics like caster wheel types, load distribution, all-terrain casters, and bearing types, offering a comprehensive guide for businesses, facilities managers, and engineers.

What Are Casters?

Before diving into the science of caster selection, it’s essential to understand what casters are and how they work. Casters, also known as castor wheels, are small wheels attached to the bottom of objects to enable them to move smoothly over surfaces. Casters come in a variety of shapes, sizes, and materials, with each designed for specific functions and environments.

At their core, casters are designed to facilitate movement. These devices can be installed on carts, industrial machines, medical equipment, and furniture. Depending on the design, casters may rotate or swivel to allow for smooth movement, or they may be fixed in a straight line to ensure stability.

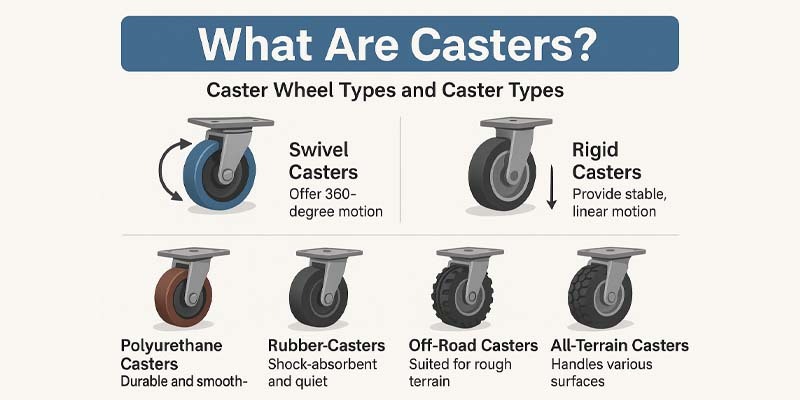

Caster Wheel Types and Caster Types

To make an informed decision about casters, understanding the various caster wheel types and caster types is crucial. Each type offers different benefits, and the choice between them depends on the environment and requirements of the application.

Swivel Casters

Swivel casters are among the most common types, offering a 360-degree range of motion. These casters can rotate in any direction, making them ideal for maneuvering equipment around tight corners or obstacles. Their design allows for superior mobility, which is why they are often used in environments where directional control is essential. Swivel casters are typically used in industries like manufacturing, healthcare, and retail.

Rigid Casters

In contrast to swivel casters, rigid casters do not swivel. These casters only move in a straight line, providing stability and directionality. Rigid casters are ideal for applications where precise control over movement is not necessary, such as in applications where equipment must move in only one direction, like along a conveyor belt. These casters are commonly used in industrial settings where stability is crucial.

Polyurethane Casters

Polyurethane casters are made from a strong, durable material that is resistant to abrasion, chemicals, and wear. These casters provide a smooth, quiet ride and are ideal for hard surfaces like concrete, tile, and asphalt. Their durability makes them well-suited for environments that require heavy-duty applications, such as warehouses or manufacturing plants. Polyurethane casters also have the added benefit of reducing floor damage compared to metal casters.

Rubber Casters

Rubber casters are designed to provide a soft, shock-absorbent ride. These casters are ideal for noise reduction, making them suitable for indoor environments like hospitals and offices. Rubber casters are also effective at absorbing shocks and vibrations, which helps protect both the caster and the surface it moves over. These casters are best used in environments where noise control and protection from vibrations are essential.

Off-Road Casters

For rough or uneven terrains, off-road casters are specifically designed to handle challenging surfaces such as gravel, dirt, and mud. Off-road casters are typically larger and feature wider wheels, which help them navigate rough, uneven ground without sinking or becoming stuck. These casters are commonly used in construction sites, outdoor machinery, and heavy-duty vehicles.

All-Terrain Casters

All-terrain casters are similar to off-road casters but are designed to handle a wider range of surfaces, including gravel, dirt, and pavement. These casters are perfect for environments where both outdoor and indoor mobility are required, offering versatility and robust performance across various terrain types. All-terrain casters often come with larger wheels to ensure that they can withstand and perform on rough surfaces without compromising mobility.

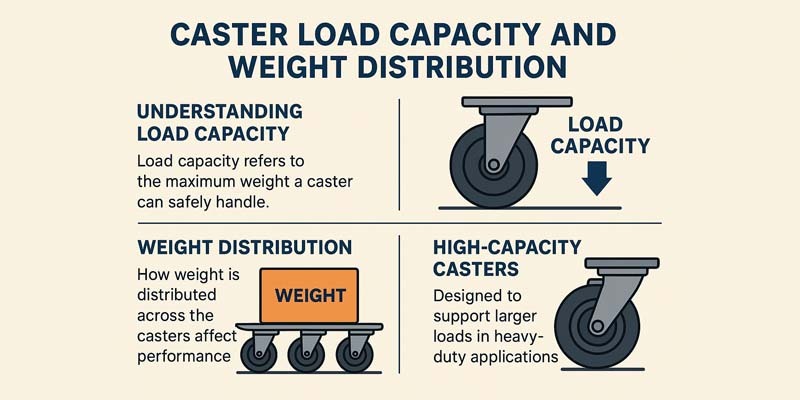

Caster Load Capacity and Weight Distribution

One of the most important considerations when selecting casters is the load capacity. The load capacity refers to the maximum weight that a caster can safely handle. Exceeding the load capacity can cause the caster to fail, resulting in equipment damage or personal injury.

Understanding Load Capacity

When calculating the load capacity, it is important to consider both the total weight of the object being moved and how that weight is distributed across the casters. Load capacity is usually specified by the manufacturer, and it is essential to adhere to these guidelines to avoid damaging the caster or equipment.

Weight Distribution

The way weight is distributed across the casters can significantly affect their performance. In an ideal scenario, the weight is uniformly distributed, meaning that each caster shares an equal portion of the total weight. This ensures smoother movement and reduces the strain on any single caster, which helps extend its lifespan. However, in many cases, the load may not be evenly distributed. For instance, heavy equipment or machinery may place more weight on one side, requiring casters with higher load capacities or additional casters to compensate for the uneven weight distribution.

High-Capacity Casters

For heavy-duty applications, high-capacity casters are designed to support larger loads. These casters are typically made from stronger materials such as steel and feature enhanced bearings that allow them to bear heavy weights without compromising mobility. High-capacity casters are commonly used in industrial applications, such as moving large machinery or equipment.

Types of Surfaces and Their Impact on Caster Selection

The surface on which a caster will be used plays a significant role in determining its performance. Different surfaces exhibit varying degrees of friction, smoothness, load-bearing capacity, and durability. Understanding how these factors influence caster performance is essential for making the best selection. The right caster can reduce operational costs, enhance efficiency, and extend the lifespan of both the caster and the equipment. Let's explore the different types of surfaces and how they impact caster selection.

Hard Surfaces (Concrete, Asphalt, Wood)

Hard surfaces, such as concrete, asphalt, and wood, are commonly encountered in industrial and commercial environments. These surfaces tend to be smooth, rigid, and durable, providing minimal resistance to casters. However, despite their toughness, they can still present challenges when selecting the appropriate caster.

Characteristics of Hard Surfaces

Hard surfaces are typically flat and smooth, but they can vary in texture, with some floors being rougher than others. For instance, concrete floors can have variations in their texture depending on whether they are polished, rough, or exposed aggregate. Asphalt, though also durable, can become rough over time, particularly in areas with high traffic or in outdoor environments. Wood surfaces, on the other hand, often have a natural grain that can affect caster movement, although it generally provides good traction.

Casters for Hard Surfaces

For hard surfaces, polyurethane casters are generally the best choice. Polyurethane is a durable material that provides a smooth roll and excellent resistance to wear and tear. It is particularly advantageous in high-traffic environments where heavy equipment or machinery needs to be moved frequently. Polyurethane casters reduce friction and make movement easier, which is particularly important when transporting large, heavy loads. Additionally, they are resistant to many common chemicals, oils, and solvents, making them suitable for industrial environments.

Another benefit of polyurethane casters is their ability to absorb shocks, making them ideal for environments where equipment needs to be moved over long distances or at high speeds. They also protect the surface from damage, preventing floor markings and indentations that can occur with harder materials.

For high-capacity applications, metal casters may be appropriate, especially when handling very heavy loads. Metal casters, such as those made from steel or aluminum, offer strength and durability and are often equipped with larger wheels to help distribute weight evenly. These casters are designed to withstand high-impact conditions without compromising on mobility. However, it is important to note that metal casters can cause damage to the floor over time, so it's essential to ensure that the surface is well-maintained to avoid unnecessary wear.

Maintenance Considerations for Hard Surfaces

While polyurethane casters are well-suited for hard surfaces, it is crucial to maintain the floor’s condition to maximize caster lifespan. For example, uneven or cracked concrete can cause casters to wear unevenly, leading to operational inefficiencies. Routine floor maintenance and cleaning are necessary to keep both the casters and the surface in optimal condition.

Soft Surfaces (Carpet, Vinyl Flooring)

Soft surfaces, such as carpets and vinyl flooring, are commonly found in office settings, retail environments, and homes. These surfaces can present unique challenges for casters, as their soft texture can cause significant friction or even damage both the caster and the surface if the wrong type of caster is used.

Characteristics of Soft Surfaces

Soft surfaces like carpets are more flexible than hard surfaces, which can cause casters to sink into the material. Carpets are often made from fibers like wool, nylon, or polyester, which can create resistance when casters attempt to roll across them. Vinyl flooring, although relatively smooth, can still present challenges due to its tendency to dent under heavy weight. Unlike hard surfaces, soft materials like carpet can increase rolling resistance, which can make it more difficult to move equipment or furniture.

Casters for Soft Surfaces

When selecting casters for soft surfaces, it is important to choose wheels that are soft yet durable, with the ability to roll smoothly without causing damage to the surface. Soft rubber casters or nylon casters are ideal for these surfaces, as they provide a good balance of durability and low rolling resistance. These materials help the casters glide smoothly across the floor without causing indentations or damage to the material.

Soft rubber casters are particularly beneficial for high-mobility environments, such as offices or healthcare settings, where noise reduction and floor protection are key considerations. These casters provide excellent shock absorption and reduce the amount of noise generated during movement. Their smooth operation prevents carpets from being damaged by the constant friction that can occur with harder casters.

For vinyl flooring, softer casters are essential to prevent scratches or scuff marks that can be caused by harder materials. Rubber casters help to ensure that the floor remains intact, while still providing a smooth, quiet roll.

Considerations for Heavy Loads on Soft Surfaces

For environments where heavy loads need to be moved over carpet or vinyl flooring, larger casters are often necessary to distribute the weight more evenly. Larger wheels reduce the risk of casters sinking into the carpet or creating unsightly indentations in the vinyl flooring. Larger casters with a wider diameter also help to reduce rolling resistance, allowing equipment to move more easily without causing strain on the floor or the caster.

It is also important to ensure that the casters' weight-bearing capacity matches the load being moved. Using casters that are too small or insufficiently rated for the load can lead to excessive wear and tear, as well as potential damage to both the caster and the floor.

Maintenance Considerations for Soft Surfaces

Casters on soft surfaces require more frequent inspection and maintenance to ensure optimal performance. Carpet fibers, dust, and debris can accumulate around the wheels, causing resistance and potentially leading to wheel damage. Regular cleaning and maintenance of both the casters and the floor are essential to ensure smooth operation.

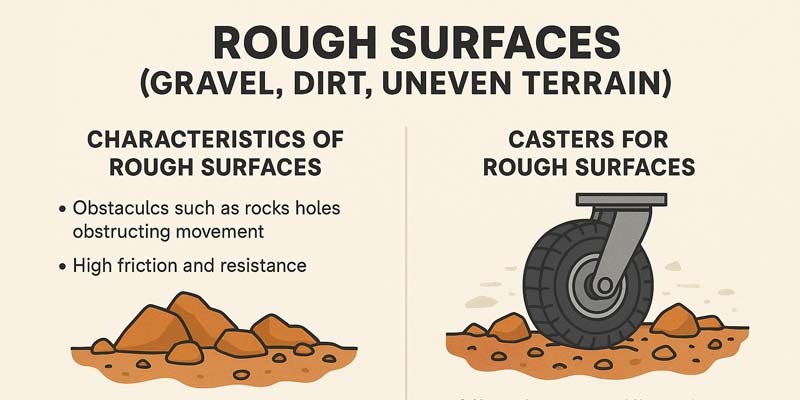

Rough Surfaces (Gravel, Dirt, Uneven Terrain)

Rough surfaces, such as gravel, dirt, and uneven terrain, are typically encountered in outdoor environments or in industrial settings where equipment needs to be moved across construction sites, farms, or warehouses. These surfaces pose unique challenges because of their uneven texture and irregularities.

Characteristics of Rough Surfaces

Rough surfaces can vary in terms of their consistency, with gravel and dirt often providing obstacles like rocks and holes that can obstruct movement. These surfaces can create a lot of friction and resistance, making it difficult for standard casters to roll smoothly. In addition to that, they can also pose risks of damaging both the equipment and the casters due to the abrasiveness of the materials.

For these reasons, rough surfaces require casters that are specifically designed to handle these challenges, ensuring both mobility and durability in harsh conditions.

Casters for Rough Surfaces

When moving equipment across rough terrain, off-road casters or all-terrain casters are the ideal solution. These casters are designed with large, wide wheels that can handle bumps, rocks, and other irregularities found in gravel, dirt, and other rough surfaces. The larger wheels help distribute the load more evenly across the surface, preventing the caster from getting stuck or bogged down by debris.

Off-road casters are typically made from highly durable materials such as rubber or polyurethane, which can withstand harsh environmental conditions. Rubber casters, in particular, offer excellent shock absorption, allowing for smoother movement over rough ground while reducing the impact on both the caster and the surface. Polyurethane casters, on the other hand, are more resistant to abrasion and wear, making them an excellent choice for high-traffic outdoor environments.

All-terrain casters are similar to off-road casters, but they offer greater versatility. They are designed to perform well on a variety of surfaces, including rough ground, asphalt, and even smooth floors. These casters are typically used in environments where equipment needs to be moved both indoors and outdoors, providing a solution that can handle all types of surfaces with ease.

Considerations for Heavy Equipment on Rough Surfaces

In applications where heavy equipment needs to be moved across rough terrain, high-capacity casters are essential. These casters are designed to support large loads without compromising mobility or safety. High-capacity casters often feature reinforced wheels and bearings, making them durable enough to handle the intense stress that rough surfaces can place on casters.

Casters used in these environments also need to be resistant to damage from environmental factors, such as moisture, dirt, and extreme temperatures. This ensures that the casters will continue to perform well, even under challenging conditions.

Bearing Types and Their Role in Caster Performance

Bearings are critical components that influence the performance of casters. They reduce friction and allow the caster wheels to rotate smoothly. There are several different types of bearings, each suited for specific applications.

Ball Bearings

Ball bearings are the most commonly used type of bearing in casters. They consist of small steel balls that rotate within a raceway, reducing friction and allowing the caster to move smoothly. Ball bearings are versatile and can handle a variety of applications, making them suitable for use in most industries.

Roller Bearings

Roller bearings are typically used for high-load applications. They consist of cylindrical rollers that distribute the load over a larger surface area, providing greater strength and durability compared to ball bearings. Roller bearings are ideal for high-capacity casters used in industrial settings.

Needle Bearings

Needle bearings are similar to roller bearings but are designed with smaller, elongated rollers. This design allows for a higher load capacity in a smaller space, making them ideal for compact, high-load applications. Needle bearings are often used in casters that need to support heavy machinery or equipment.

Sealed Bearings

Sealed bearings are designed to keep dirt, dust, and other debris out of the bearing, preventing contamination and reducing wear. Sealed bearings are ideal for applications where cleanliness is important, such as in hospitals or food processing environments. They also help extend the lifespan of the caster by keeping the bearing lubricated and free from contaminants.

Caster Maintenance and Wheels Maintenance

Casters are integral to the smooth operation of many pieces of equipment and machinery, whether in industrial settings, healthcare facilities, or warehouses. Since casters are exposed to constant use and wear, maintaining them properly is essential to prolong their lifespan and ensure consistent performance. Without regular maintenance, casters can degrade, affecting both their mobility and the surfaces they roll over. Proper caster maintenance will not only keep the wheels in good working order but also help to prevent costly repairs or replacements. In this section, we will dive deeper into the various maintenance tasks that are essential for keeping casters performing at their best.

Caster Maintenance Tasks

The primary maintenance tasks for casters include lubrication, cleaning, inspection, wheel alignment, and bearing replacement. Let's explore each one in more detail:

1. Lubrication: Ensuring Smooth Movement

Lubrication is one of the most important maintenance tasks for casters. Over time, the bearings within the caster wheels can suffer from increased friction, which leads to wear and tear. Lubricating the bearings periodically helps reduce friction, allowing the caster to move smoothly and with less effort. Regular lubrication also prevents rust and corrosion, which can occur when metal parts rub together without sufficient grease.

It is important to use the manufacturer-recommended lubricant to ensure compatibility with the materials used in the caster and bearing. Depending on the caster's environment (indoor, outdoor, wet, or dry), the lubricant used should be suitable for the specific conditions. For instance, heavy-duty casters may require more frequent lubrication, especially if they are used in high-stress environments, such as industrial warehouses or factories.

To lubricate casters properly, remove any debris or dirt around the bearing and apply the lubricant directly to the moving parts. Ensure that the lubricant seeps into the bearing, allowing the parts to move smoothly without excessive friction.

2. Cleaning: Preventing Damage from Dirt and Debris

Cleaning is another critical part of caster maintenance. Over time, dirt, dust, grease, and other debris can accumulate around the casters, affecting their performance. These particles can create unnecessary friction between the wheel and the surface, reducing the caster’s rolling efficiency and potentially leading to the wear of the wheel material and bearing.

Cleaning the casters regularly helps to prevent damage by removing accumulated debris. Use a soft brush or cloth to wipe off any dirt or dust. If the casters are exposed to grease or other stubborn substances, consider using a mild degreaser or a cleaning solution to break down the buildup. After cleaning, ensure the caster is dry before lubrication to avoid trapping moisture, which can cause rust and corrosion.

When cleaning casters, pay close attention to the bearings, as they are the most vulnerable to dirt and debris. Over time, if dirt is allowed to accumulate in the bearing, it can interfere with smooth movement, making it harder for the wheels to turn. Regular cleaning will extend the caster's life and ensure optimal function.

3. Inspection: Catching Signs of Wear and Tear Early

Regular inspection of casters is essential for catching signs of wear and tear before they become more severe. Frequent use can cause the wheels and bearings to degrade over time, and if not addressed, these issues can affect mobility and cause damage to the surfaces they are rolling over. Inspections should be carried out on a routine basis to check for the following:

- Cracks and Chips: Over time, the wheel material may develop cracks or chips, especially if the casters are exposed to extreme temperatures or harsh surfaces. If the damage is significant, the caster should be replaced immediately to avoid further issues.

- Flat Spots: Flat spots on the wheels can occur if the caster is exposed to uneven or excessive load distribution, or if the equipment is left in one position for too long. This can create bumpy movement, making the caster difficult to roll. It's important to check the wheels for signs of flattening and replace them if needed.

- Worn Bearings: The bearings inside the caster can wear out due to constant friction. If you hear a grinding sound or notice increased resistance while moving the caster, the bearings may be damaged and need replacement.

- Misalignment: If the casters are misaligned, it can cause uneven wear and lead to the wheels dragging or resisting movement. Misalignment can also result in unnecessary stress on the caster’s frame and bearing, potentially leading to premature failure.

By conducting thorough inspections, you can identify any signs of wear early on and address them before they cause more extensive damage.

4. Wheel Alignment: Preventing Uneven Wear

Proper wheel alignment is critical to ensuring that the casters perform optimally. Misaligned wheels can lead to uneven wear, reduced mobility, and strain on the caster’s frame and bearings. Misalignment occurs when the caster’s wheels are not positioned correctly in relation to the load, which can lead to dragging, instability, or difficulty rolling.

To check for alignment issues, place the equipment or cart on a flat, level surface and observe how the casters roll. If the casters don’t move smoothly or seem to skew to one side, realign them to ensure they are positioned correctly. In some cases, wheel misalignment may result from damage to the frame, which should be addressed immediately.

Realigning the wheels will ensure that the load is distributed evenly, which reduces friction and minimizes stress on the bearings and wheel. Regular alignment checks help keep casters rolling smoothly and contribute to a longer lifespan.

5. Bearing Replacement: Ensuring Smooth Rolling

Bearings are the internal components of casters that allow the wheels to rotate smoothly. Over time, the bearings can become damaged or worn due to constant friction, particularly in high-load or high-speed applications. If you notice any grinding, resistance, or abnormal movement, it's essential to inspect and, if necessary, replace the bearings.

To replace a damaged bearing, carefully remove the wheel from the caster frame, then remove the old bearings and replace them with new ones. When selecting replacement bearings, ensure they match the specifications of the original bearing to maintain optimal performance.

In addition to replacing worn-out bearings, it's important to lubricate them regularly to reduce wear and maintain smooth movement. Proper bearing care will ensure that your casters continue to perform effectively, even in demanding environments.

Trade-offs in Caster Selection

When selecting casters for a particular application, there are several trade-offs to consider. Casters come in a variety of designs, materials, and load capacities, each offering different benefits and limitations. Understanding these trade-offs will help you make the best choice for your specific needs.

1. Size and Maneuverability

Larger casters often perform better on rough or uneven surfaces because they distribute the load more evenly and can handle obstacles without getting stuck. However, larger casters tend to be less maneuverable in tight spaces, which may be a drawback in environments like hospitals, warehouses, or offices, where space is limited. Conversely, smaller casters are more maneuverable and work well in tight spaces but may not perform as well on rough terrain.

Choosing the right balance between size and maneuverability is essential, depending on your workspace and how often the casters will need to navigate narrow aisles or corners.

2. Durability vs. Performance

Some casters, such as those made from polyurethane or metal, are highly durable and suitable for heavy-duty applications. These casters can withstand high loads, resist abrasion, and offer long-lasting performance. However, they may not provide the smoothest ride on softer surfaces like carpet or vinyl. On the other hand, rubber casters offer a smoother, quieter ride but may not be as durable on rough surfaces or heavy-duty applications.

When selecting casters, you need to weigh the durability of the material against the performance needed for your specific environment. For example, if you require heavy-duty casters for industrial equipment, durability may be more important than ride comfort. Alternatively, for office furniture or medical equipment, performance, and smoothness may be the priority.

3. Load Capacity vs. Mobility

High-capacity casters are designed to handle heavy loads, making them ideal for moving large machinery or equipment. However, these casters are typically bulkier and may not provide the same level of mobility as smaller casters. If your equipment needs to be moved frequently or across long distances, you may need to prioritize mobility by opting for smaller casters with less weight capacity.

While smaller casters may be more maneuverable and suitable for lighter loads, they may struggle to support heavier equipment. Therefore, balancing load capacity and mobility is crucial when selecting casters for specific applications.

Final Thoughts

Choosing the right caster for different surfaces requires a deep understanding of the various factors that influence caster performance. By considering factors such as surface type, load capacity, bearing types, and maintenance, businesses can select the most suitable casters for their specific needs.

Casters play a vital role in ensuring smooth mobility and efficient operations in a wide range of industries. Understanding how different surfaces impact caster performance and making informed decisions will help businesses improve their equipment's longevity, reduce downtime, and optimize workflow.

Email US

Email US

Hours

Hours

Visit Our Showroom

Visit Our Showroom