Which wheel?

Posted by howard on Jun 15th 2017

Our website has seven categories of wheels. When you click on a wheel, you’ll see it’s subdivided into different types of choices under that heading. Example: Click the “rubber” category and you’ll see 8 types of rubber wheels. How do you select one? I know the application and how much capacity we need (see previous blog), but there are many wheels that could possibly work.

Our website has seven categories of wheels. When you click on a wheel, you’ll see it’s subdivided into different types of choices under that heading. Example: Click the “rubber” category and you’ll see 8 types of rubber wheels. How do you select one? I know the application and how much capacity we need (see previous blog), but there are many wheels that could possibly work.

New wheels are introduced all the time. We talk with the people who make them so we can understand what the product does for you.

It’s time to discuss where these wheels are used. We’ll start with metal.

“Why would I choose a metal wheel?”

A foundry who specializes in metal wheels says this criteria is important:

- DURABILITY. You need a wheel that used in rigorous applications. It will stand up to bad floors or abuse. Dirt, oil, or metal chips won’t stay on wheel.

- WEIGHT. You need to move a lot of pounds.

- ENVIRONMENT. You need a wheel that can withstand extremes in temperatures.

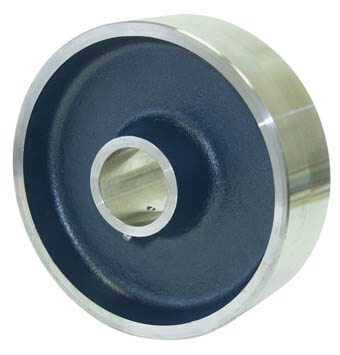

As you can see under the metal wheel heading, we offer three types of metal wheels—cast iron, ductile iron, and forged steel.

CAST IRON. An economical choice that’s available in a wide range of diameters and capacities. It’s made from metal that is cast into its shape.

DUCTILE IRON. Also cast like cast iron, but can survive more concussion and abuse. Capacity per wheel is dramatically higher than cast iron.

FORGED STEEL. This wheel is heat treated and compressed into its size. This process creates a wheel with high capacities and very high tensile or strength.

Don’t use a metal wheel on floor that needs protection such as linoleum or terrazzo. There is no “resiliency” in metal so it would be a poor choice for products that need a cushioned ride. And take into account that metal is noisy.

Our next discussion will cover nylon glass filled wheels.

Email US

Email US

Hours

Hours

Visit Our Showroom

Visit Our Showroom